Distinctive Features of Monel 400 Wire Mesh

Remarkable Resistance To Corrosion

Due to the Monel 400’s pitting and corrosion resistance, it stands as one of the best candidate materials for marine, industrial, and chemical usage. Not only does Monel 400 survive in acidic and alkali conditions, but it also withstands exposure to hydrofluoric acids and sulfuric acids.

Remarkable Strength and Toughness

Monel 400’s corrosion resistance and durability in harsh environments are superior when it is compared to other commonly seen austenitic stainless steel wire mesh materials.

Unlike ordinary ferritic and austenitic stainless steel woven wire fabrics, Monel 400 wire mesh can endure environments with high pressure and mechanical stress.

It is appropriate for both cryogenic and high-temperature settings as it retains its integrity under very high or low temperature changes.

Monel 400 is highly suitable, and it performs efficiently in elevated conditions. It is used in heat exchangers, and also in boiler parts and other equipment responsible for thermal processes.

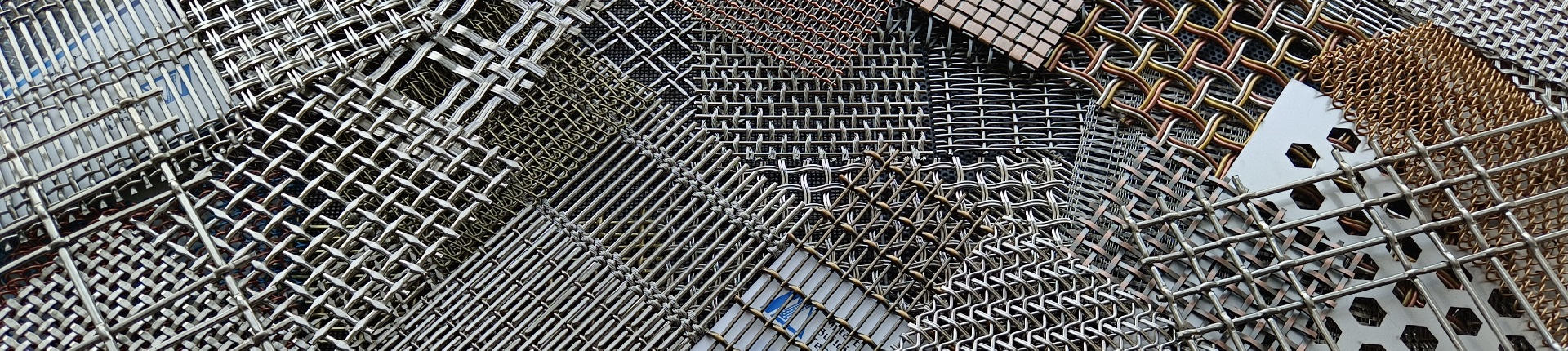

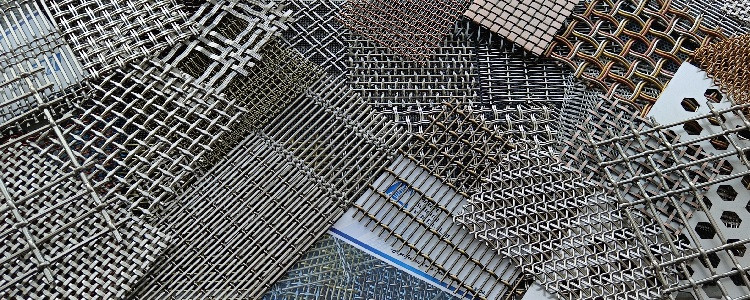

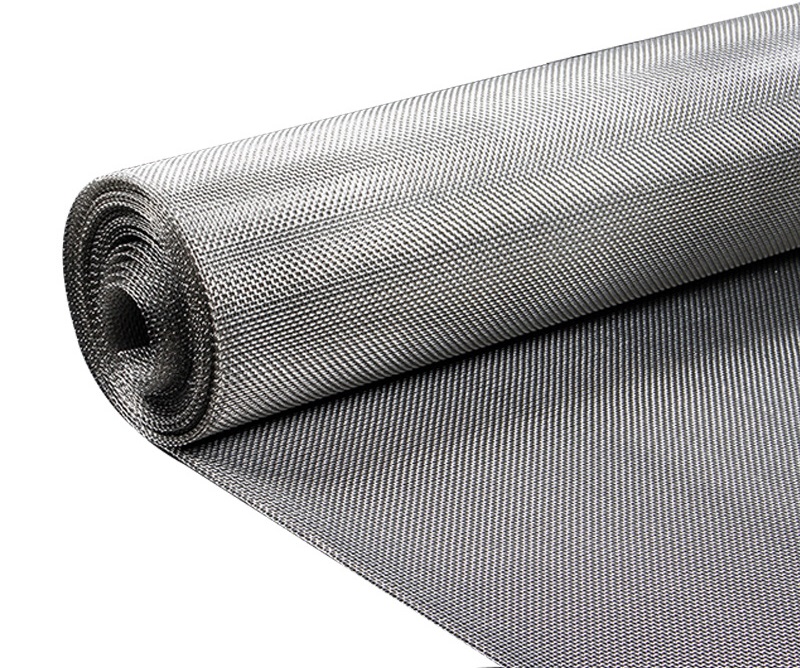

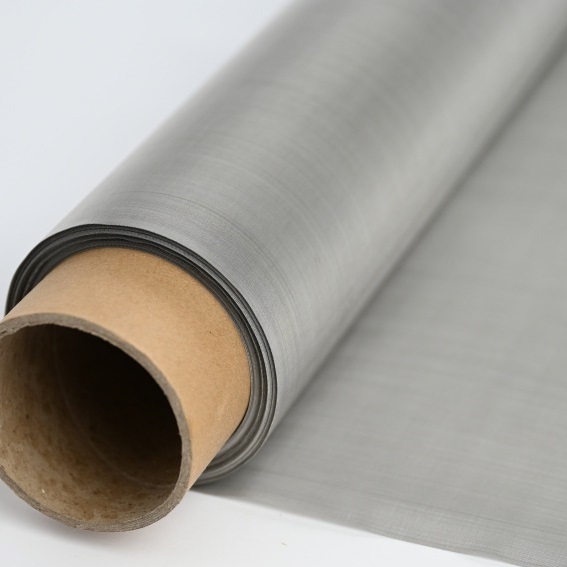

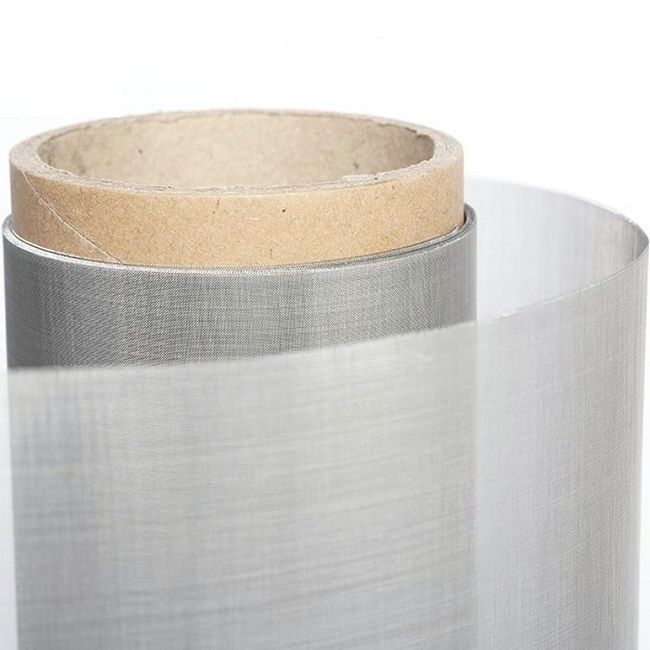

Some Monel 400 wire mesh rolls are readily available in our warehouse as stock, in different weaving styles like plain weave, twill weave, plain Dutch, and twill Dutch. Whenever we customize monel wire mesh for overseas wire mesh distributors or wire mesh factories, we can weave a little bit more than needed. In that case, we can keep a few common specification monel wire cloth in stock for some small projects needed in the global market.

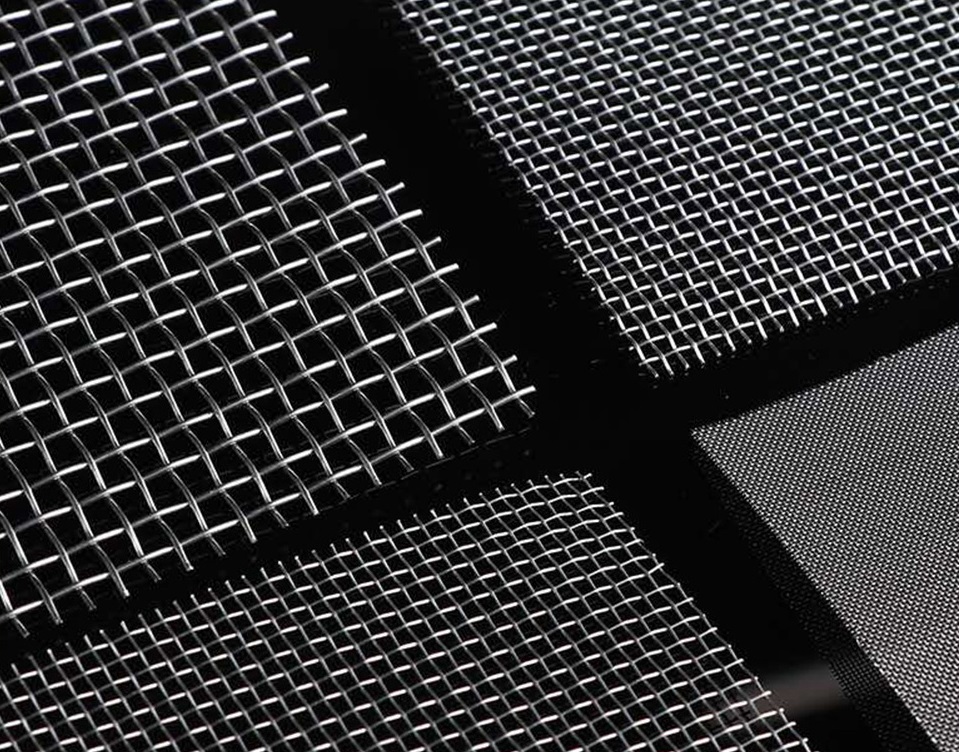

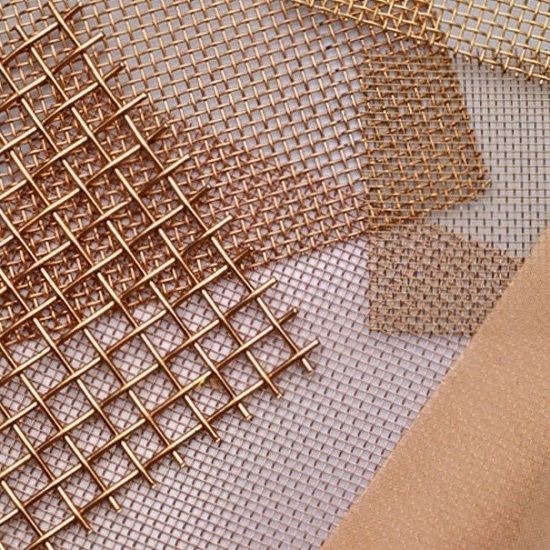

As for the coarse wire mesh panels to be made in Monel 400 alloy, we can quickly customize the Monel wires and draw the wires to the desired diameter and weave the wire mesh panels via pre-crimping technique, which is always fast and flexible for wire mesh panels’ manufacturing. The most widely used pattern would be the double crimped wire mesh pattern, which resembles plain weave, and there is almost no difference in their appearance when compared with plain weave wire mesh.

And the other frequently used weave pattern is inter-crimped wire mesh, which is suitable for most of the big opening coarse wire mesh, either for super alloy, or for regular austenitic stainless steel wire mesh sheets, like 304, 316.

Here with Metart Building Tech, customization based on specific application requirements can always be achieved to make your customers happy.

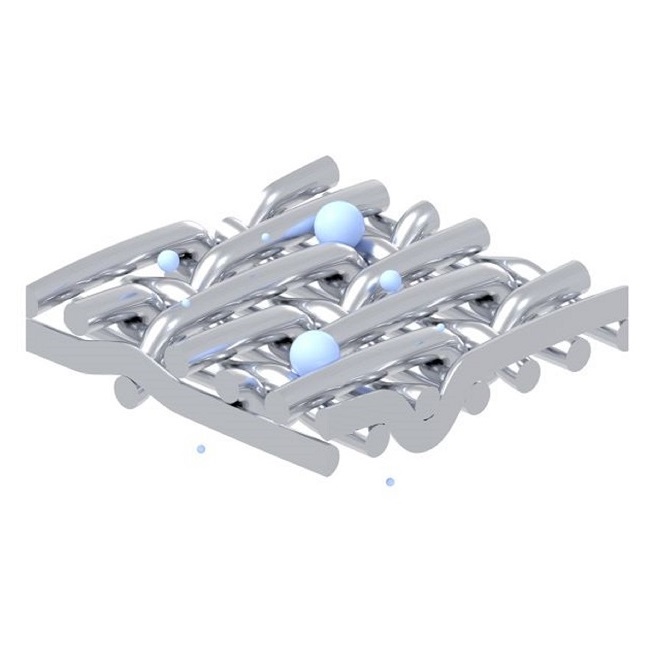

Specific functionality can be performed accurately by adjusting the diameters of the wire and the sizes of the opening.

Applications of Monel Wire Mesh

Monel wire mesh is versatile and is used in various applications due to its superior qualities and high efficiency in extreme conditions.

1. Marine and Offshore Industries

Monel 400 is used in seawater filtration systems, pumps, and strainers, and it does not corrode in aggressive saltwater environments.

This is key offshore oil drilling activities where components have to withstand long periods of exposure to saline conditions and need to be corrosion resistant.

2. Chemical and Petrochemical Processing

Montel 400 wire mesh is very common in chemical processing plants, especially where hazardous chemicals, acids, and alkalis are used.

In these areas, it is essential for heat exchangers, distillation units, and reactor vessels, where chemical stability is very important.

3. Aerospace and Defence

In applications pertaining to aerospace, such as fuel tanks, hydraulic lines, and turbine parts, high strength and corrosion-resistance are best served by Monel 400 wire mesh and wire cloth.

In addition, its preferred use in the military and defence is due to its ability to withstand extreme temperatures and harsh conditions.

4. Filtration and Separation Processes

In oil, gas, and water filtration systems, Monel 400 wire mesh is used for purification due to effective contaminant removal.

Its application in food processing, pharmaceuticals, and environmental filtration is due to the absence of harmful chemical reactions that would otherwise reduce its effectiveness.

Why Choose Metart Building Tech for Monel 400 Wire Mesh?

Metart Building Tech’s goal is to provide materials that are precise and of high quality. Our Monel 400 wire mesh is manufactured to the highest standards, which guarantees exceptional durability and optimal performance.

Our Commitment to Excellence:

• Premium-Quality Materials: To meet customer satisfaction, Monel 400 wire mesh is manufactured from high-grade nickel-copper alloys.

• Customization & Fabrication : In order to meet industrial requirements, we provide an array of openings, types of weave, and varying thicknesses. Regarding the finished wire mesh products, they can be made into different forms, including the most widely exported wire mesh rolls, slitted small wire cloth rolls, wire mesh panels, wire mesh discs, wire mesh rings, and their deep-processed forms, including cylinders and custom filters.

• Stringent Quality Control: To ensure repeatability and dependability, we strictly control the quality of our output to meet ASTM E2016 and ISO9044 (industrial woven wire cloth standard).

• Global Reach & Trusted Supplier: Monel 400 wire mesh is exported all over the world with expert consultation and technical support for years. We have amassed a reputable client base due to our expertise.

Conclusion

In the circles where exceptional corrosion resistance paired with strength and longevity is needed, Monel 400 wire mesh and cloth are staples. Metart Building Tech truly caters to your business needs with premium quality bespoke Monel wire mesh rolls and panels for marine, chemical processing, and aerospace industries.

With Metart Building Tech's Monel 400 wire mesh, high performance in extreme environments is a reality.

Contact Metart Building Tech to see all our products and let us provide the expert help you need in determining the right solution for your requirements.

+86 158 0318 7372 / +61 435 598 786

+86 158 0318 7372 / +61 435 598 786

.jpg)

+86 158 0318 7372 / +61 435 598 786

+86 158 0318 7372 / +61 435 598 786