Material: Cold rolled mild steel sheets, hot rolled mild steel sheets

Material: Pre-galvanized sheet, aluminum sheets, SS201,304,316L sheets

Material: brass sheets, copper sheets, and other special alloy sheets

Thickness: Ranging from 0.5mm to 20mm

Sheet Size: Please refer to the following contents.

Pattern: 60 degree staggered, Straight Pattern, 45 degree staggered.

Finish: Mill Finish,Powder Coating, PVDF Coating, Painting

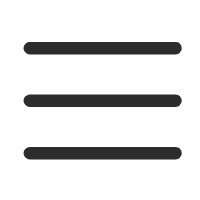

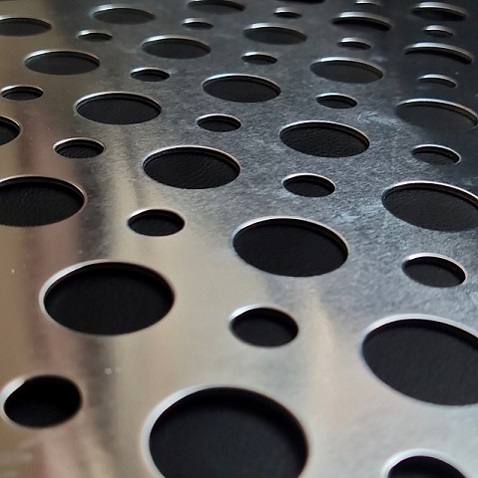

GET A QUOTEPerforated Sheets are also known as perforated metal, perforated plates, perforated mesh, punched sheets, punched metal mesh, etc.

As we can tell easily tell from its structure, it is created by subjecting metal sheets or coils to a mechanical punching or stamping process, resulting in a pattern of precisely placed holes. These holes can vary in size, shape, and spacing, depending on the specific requirements of the application.

Perforated metal is a fascinating material that finds widespread use in a multitude of applications due to its versatility, durability, and aesthetic appeal.

As a experienced perforated sheets manufacturer from China, METART BUILDING TECH are dedicated in the production and innovation of perforated screen mesh production. Please email or call us to get a free quotation for your perforated sheets projects.

HOW IS PERFORATED SHEET MANUFACTURED?

Have you ever gazed at a perforated sheet and marveled at the precision and artistry behind it? If you're curious about the magic that turns raw metal into these functional works of art, then this video is your backstage pass to the captivating world of perforated sheet manufacturing.

WHAT ARE THE KEY SPECIFICATIONS OF PERFORATED PLATES?

Raw Material: Cold rolled mild steel sheets, hot rolled mild steel sheets, pre-galvanized sheets, aluminum sheets, stainless steel 304, Stainless steel 316L sheets, brass sheets, copper sheets, and other special alloy sheets.

Standard Sheet Size:

1000x2000mm, 1200x2000mm,1200x2400mm,1220x2440mm,1250x2500mm,1250x3000MM, depending on different materials.

Other custom sizes are accepted.

Round Hole Patterns: 60° staggered pattern, 45° staggered pattern, straight pattern.

Finish: Mill Finish, Powder Coating, PVDF Coating, Painting

Packing: Steel Pallets, Plywood Cases.

►Perforated Steel - The most commonly used perforated material for industrial application.

Perforated steel sheets, often made from carbon steel, are known for their exceptional strength and durability. The high tensile strength of steel makes it an ideal choice for applications that demand structural integrity and load-bearing capabilities. Additionally, steel offers excellent fire resistance and impact resistance, making it suitable for heavy-duty industrial environments, construction projects, machinery components, and automotive parts.

As a manufacturer of quality perforated metal products, we offer a diverse range of options for our customers. Among our offerings, we specialize in providing perforated cold rolled steel sheets ranging from 0.5mm to 2.5mm in thickness. These sheets are known for their excellent durability and smooth finish.

The cold rolled steel sheets undergo a meticulous manufacturing process. It is formed by compressing the steel between rollers at room temperature, resulting in improved surface quality and dimensional accuracy. The perforations are created through precise mechanical punching or stamping techniques, allowing for customization in terms of hole size, shape, spacing, and pattern.

In addition to our cold rolled steel sheets, we also offer perforated hot rolled plates ranging from 2.5mm to 5mm in thickness. Hot rolled steel is known for its robustness and toughness, making it suitable for heavy-duty applications. Our perforated hot rolled steel plates undergo a similar punching or stamping process by CNC punching machines to create the desired pattern of perforations.

For customers with specific requirements that go beyond the provided thickness range, we offer customizations. We can accommodate thicknesses above 5mm through either punching or laser cutting methods. These processes ensure precise hole placement and maintain the structural integrity of the steel material.

Standard width: 1000MM and 1250MM

Standard length: Within 3000MM for sheet,wpre-galvanized,within 20Meter for small rolls or big perforated coils.

►Perforated Galvanized Steel - An Upgraded Option for Enhanced Protection and Minimal Cost Difference

Galvanized steel undergoes a zinc coating process, which enhances its corrosion resistance and longevity. Perforated galvanized steel sheets are commonly used in outdoor applications where exposure to harsh weather conditions and corrosive elements is a concern. The zinc coating acts as a sacrificial layer, protecting the underlying steel from rust and corrosion. Industries such as agriculture, architecture, transportation, and infrastructure extensively utilize perforated galvanized steel in products like fences, gates, guardrails, and noise barriers.

To further enhance the weather resistance, durability, and aesthetic appeal of a d perforated sheet, an extra powder coating finish is often applied to the perforated sheets.

Standard width: 1000MM and 1250MM

Standard length: Within 3000MM for sheet,wpre-galvanized,within 20Meter for small rolls or big perforated coils.

►Perforated Aluminum - The Most Popular Architectural Perforated Material.

Perforated aluminum sheets offer a unique combination of lightweight properties and high strength, making them an excellent choice for applications that require both structural integrity and reduced weight. Aluminum possesses natural corrosion resistance, even without additional coatings, making it suitable for outdoor applications and environments with high humidity. Industries such as aerospace, automotive, electronics, interior design, and acoustics utilize perforated aluminum for its aesthetic appeal, lightweight construction, and resistance to corrosion.

Most Popular Types of Perforated Aluminium sheets including: Grade1060, Grade 3003, Grade5052.

Perforated aluminum is widely recognized and favored in building facades and architectural applications due to its versatility, aesthetic appeal, and functional properties. Its popularity stems from the following factors:

Design Flexibility:

Perforated aluminum sheets offer a wide range of hole patterns, shapes, and sizes, allowing for creative and intricate designs. Architects and designers can achieve unique visual effects, create shading elements, and incorporate branding or decorative elements into building facades.

Aesthetic Appeal:

Perforated aluminum adds a modern and visually appealing touch to architectural designs. The patterns created by the perforations can play with light and shadow, adding depth and texture to the building facade. The combination of perforated panels with backlighting can create stunning visual effects during both day and night.

Ventilation and Sunlight Control:

Like other perforated metal plates and architectural mesh, perforated aluminium sheets also provide excellent ventilation and airflow, making it suitable for applications where air circulation is important, such as in parking structures or HVAC systems. Additionally, it allows for controlled sunlight penetration, reducing glare and heat gain while maintaining natural light inside the building.

To enhance the durability and weather resistance of perforated aluminum, it is common to apply powder coating or PVDF (Polyvinylidene fluoride) painting. These finishes offer the following advantages:

Protection:

Powder coating and PVDF painting create a protective barrier on the surface of the aluminum, shielding it from environmental factors such as UV radiation, moisture, and corrosion. This helps to maintain the appearance and performance of the perforated aluminum over time.

Durability:

The powder coating and PVDF painting significantly improve the durability of perforated aluminum, making it more resistant to scratches, abrasion, and fading. This ensures that the material retains its visual appeal and functional properties even in harsh weather conditions.

Regarding the price advantages of powder coating and PVDF painting, they offer a cost-effective solution in the long run. The durability and extended lifespan of the coated or painted perforated aluminum reduce the need for frequent maintenance or replacement, resulting in cost savings over time.

The lightweight nature of aluminum is another significant advantage, especially when considering airfreight transportation. Perforated aluminum's low weight makes it more cost-effective to transport compared to heavier materials, such as steel. This means that even after factoring in transportation costs, perforated aluminum remains competitively priced, making it a viable option for architectural projects that require air transportation.

Generally, perforated aluminum is a popular choice in building facades and architectural applications due to its design flexibility, aesthetic appeal, and functional properties. The addition of powder coating or PVDF painting enhances its durability and weather resistance. The lightweight nature of aluminum also makes it suitable for airfreight transportation, with competitive pricing even after transportation costs are factored in.

►Perforated Stainless Steel - Uncompromising Durability and Elegant Design for Diverse Applications

Stainless steel is renowned for its exceptional corrosion resistance, making it an ideal choice for applications where hygiene, durability, and aesthetic appeal are critical. Perforated stainless steel sheets find extensive use in the food processing industry, as they are easy to clean, maintain, and provide proper airflow. Other applications include mainly in filtration indsutry and in architectural design, interior decoration, noise control systems, and filtration systems where the combination of corrosion resistance and mechanical strength is essential. Additionally, stainless steel offers various finish options, such as brushed, polished, or colored, allowing for enhanced visual appeal and customization.

Perforated metal sheets provide several advantages that make them highly sought after in numerous industries:

Enhanced airflow and ventilation: The precise arrangement of holes in perforated metal enables optimal airflow and ventilation, making it suitable for applications such as HVAC systems, speaker grilles, and acoustic panels. This property is particularly valuable in environments that require efficient air circulation, temperature control, and sound management.

Filtering and screening capabilities: Perforated metal acts as an effective filter or screen, allowing the passage of specific substances while preventing the entry of unwanted particles. It finds application in water and air filtration systems, as well as particle separation in industrial processes. The ability to customize the hole size and pattern ensures that the perforated metal meets specific filtration requirements.

Aesthetic versatility: Perforated metal offers immense design potential, allowing for creativity and customization in architectural and interior design projects. The patterned perforations create visually striking effects, casting beautiful light and shadow patterns, while also providing privacy and visual barriers. It can be utilized for decorative facades, building cladding, signage, artistic installations, and innovative lighting applications.

The perforated stainless steel plates are often used in its mill finish. But for interior architectural applications, the stainless perforated plates can be also treated with really fancy colors like our architectural wire meshes, including copper plating, brass plating, antique copper plating, antique brass plating, antique bronze plating, PVD titanium plating.

Strength and structural integrity:

Perforated stainless steel maintains its structural strength despite having a portion of its material removed in the form of holes. This property makes it an excellent choice for applications that require a balance between strength and weight reduction. It can be used as a structural element in construction projects, bridges.

Perforated stainless steel is a highly versatile and durable material that finds application across various industries. It utilizes different grades of stainless steel, including the commonly used grades such as 201, 304, and 316L, as well as other special alloy sheets, including UNS.S31803, 2205 Duplex Stainless Steel Plates UNS.S32750, 2507 Duplex Stainless Steel and many other super alloy sheets.

Grade 201 Perforated Stainless Steel: This grade of stainless steel is known for its excellent corrosion resistance and high tensile strength. It is often used in applications that require good formability and low maintenance, such as automotive trims, kitchen equipment, and architectural accents.

Grade 304 Perforated Stainless Steel: Considered the most widely used stainless steel grade, 304 stainless steel offers exceptional corrosion resistance, high temperature resistance, and excellent mechanical properties. It is suitable for a wide range of applications, including food processing equipment, chemical processing, and architectural installations.

Grade 316L Perforated Stainless Steel: This grade of stainless steel is highly corrosion-resistant, making it ideal for use in environments exposed to aggressive chemicals, saltwater, and extreme temperatures. It provides superior resistance to pitting and crevice corrosion and is commonly used in marine applications, pharmaceutical equipment, and coastal architectural projects.

In addition to these grades, there are also other special super alloy sheets available for perforated stainless steel. These special alloys offer enhanced properties such as increased corrosion resistance, improved strength, and high-temperature stability. They are utilized in specialized industries like aerospace, oil and gas, and chemical processing, where demanding operating conditions require exceptional performance.

Please refer to the following standard hole configuration table.

|

Pattern # |

Hole Dia |

Centers |

Opening % |

Sheet thickness |

Material |

|||||||||||||||

|

0.5 |

0.6 |

0.8 |

0.9 |

1.0 |

1.2 |

1.4 |

1.5 |

2.0 |

2.5 |

3.0 |

4.0 |

5.0 |

MS |

AL |

SS |

|||||

|

R0.5T1.5 |

0.5 |

1.5 |

10.08 |

√ |

|

|

|

|

|

|

|

|

|

|

|

|

√ |

|

√ |

|

|

R0.6T1.5 |

0.6 |

1.5 |

14.51 |

√ |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

√ |

|

|

R0.7T1.7 |

0.7 |

1.7 |

15.38 |

|

√ |

|

|

|

|

|

|

|

|

|

|

|

|

|

√ |

|

|

R0.8T1.6 |

0.8 |

1.6 |

22.67 |

√ |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

√ |

|

|

R0.8T2.0 |

0.8 |

2 |

14.51 |

|

|

√ |

|

|

|

|

|

|

|

|

|

|

√ |

|

√ |

|

|

R1.0T2.0 |

1 |

2 |

22.67 |

√ |

√ |

√ |

√ |

√ |

|

|

|

|

|

|

|

|

√ |

|

√ |

|

|

R1.25T2.5 |

1.25 |

2.5 |

22.67 |

√ |

√ |

√ |

√ |

√ |

|

|

|

|

|

|

|

|

√ |

|

√ |

|

|

R2.0T3.0 |

2 |

3 |

40.31 |

√ |

√ |

√ |

√ |

√ |

|

|

|

|

|

|

|

|

√ |

√ |

√ |

|

|

R2.0T4.0 |

2 |

4 |

22.67 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|

|

|

|

√ |

√ |

√ |

|

|

R2.5T5.0 |

2.5 |

5 |

22.67 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|

|

|

|

√ |

√ |

√ |

|

|

R3.0T4.0 |

3 |

4 |

51.01 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|

|

|

|

√ |

√ |

√ |

|

|

R3.0T5.0 |

3 |

5 |

32.65 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|

|

|

|

|

|

|

|

|

R3.0T6.0 |

3 |

6 |

22.67 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|

|

√ |

√ |

√ |

|

|

R4.0T6.0 |

4 |

6 |

40.31 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|

|

|

√ |

√ |

√ |

|

|

R4.0T7.0 |

4 |

7 |

29.61 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|

|

√ |

√ |

√ |

|

|

R4.0T8.0 |

4 |

8 |

22.67 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|

√ |

√ |

√ |

|

|

R5.0T7.0 |

5 |

7 |

46.27 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|

|

√ |

√ |

√ |

|

|

R5.0T8.0 |

5 |

8 |

35.43 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|

|

√ |

√ |

√ |

|

|

R5.0T9.0 |

5 |

9 |

27.99 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|

√ |

√ |

√ |

|

|

R5.0T10 |

5 |

10 |

22.67 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|

|

R6.0T8.0 |

6 |

8 |

51.01 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|

|

|

√ |

√ |

√ |

|

|

R6.0T8.5 |

6 |

8.5 |

45.19 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|

|

√ |

√ |

√ |

|

|

R6.0T9.0 |

6 |

9 |

40.31 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|

|

√ |

√ |

√ |

|

|

R6.0T10 |

6 |

10 |

32.65 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|

√ |

√ |

√ |

|

|

R6.0T12 |

6 |

12 |

22.67 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|

|

R8.0T10 |

8 |

10 |

58.04 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|

|

|

√ |

√ |

√ |

|

|

R8.0T11 |

8 |

11 |

47.97 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|

|

√ |

√ |

√ |

|

|

R8.0T12 |

8 |

12 |

40.31 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|

√ |

√ |

√ |

|

|

R8.0T13 |

8 |

13 |

34.34 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|

|

R8.0T14 |

8 |

14 |

29.61 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|

|

R8.0T15 |

8 |

15 |

25.80 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|

|

R8.0T16 |

8 |

16 |

22.67 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|

|

R9.0T12 |

9 |

12 |

51.01 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|

√ |

√ |

√ |

|

|

R9.0T13 |

9 |

13 |

43.47 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|

√ |

√ |

√ |

|

|

R9.0T14 |

9 |

14 |

37.48 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|

|

R9.0T15 |

9 |

15 |

32.65 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|

|

R9.0T16 |

9 |

16 |

28.69 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|

|

R9.0T17 |

9 |

17 |

25.42 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|

|

R9.0T18 |

9 |

18 |

22.67 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|

|

R10T13 |

10 |

13 |

53.66 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|

|

√ |

√ |

√ |

|

|

R10T14 |

10 |

14 |

46.27 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|

√ |

√ |

√ |

|

|

R10T15 |

10 |

15 |

40.31 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|

|

R10T16 |

10 |

16 |

35.43 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|

|

R10T17 |

10 |

17 |

31.38 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|

|

R10T18 |

10 |

18 |

27.99 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|

|

R10T19 |

10 |

19 |

25.12 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|

|

R10T20 |

10 |

20 |

22.67 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|

|

R15T20 |

15 |

20 |

51.01 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|

|

R15T25 |

15 |

25 |

32.65 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|

|

R15T30 |

15 |

30 |

22.67 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|

|

R20T25 |

20 |

25 |

58.04 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|

|

R20T30 |

20 |

30 |

40.31 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|

|

R20T40 |

20 |

40 |

22.67 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|

|

R25T35 |

25 |

35 |

46.27 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|

|

R25T40 |

25 |

40 |

35.43 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|

|

R25T50 |

25 |

50 |

22.67 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|

|

R30T50 |

30 |

50 |

32.65 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|

|

R30T50 |

30 |

60 |

22.67 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|

Application:

1. Building metal façade,

2. Wall cladding panels.

3. Ceiling panels.

4. Sieving, general filtration, and precision filtration.

5. Roofing panels.

6. Balustrade infill panels.

7. Featured fencing system.

8. Loudspeaker covering mesh.

9. Noise control panels, sound barrier, modular acoustic wall panels.

Perforated Aluminium Security Mesh

1.8MM Perforated Aluminium Security Mesh

Privacy aluminium mesh for security screen door 2.0 or 1.4mm thick optional

Heavy DVA Privacy Aluminium Security Mesh

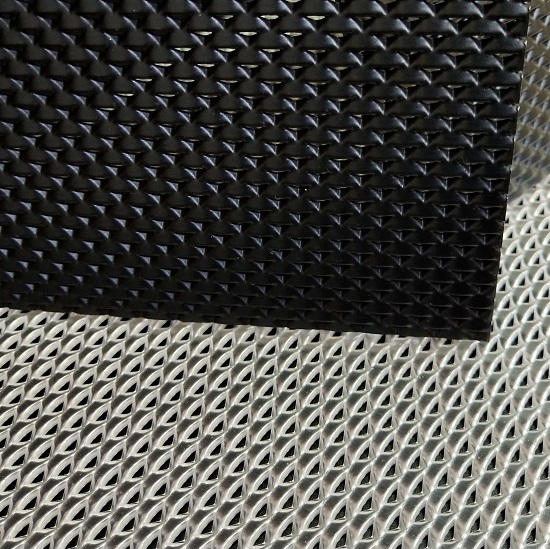

METART screens are widely been used both indoors and outdoors including interior wall arts, partition screens, decorative room dividers

Laser Cut Garden Screen / Laser Cut Wall Art

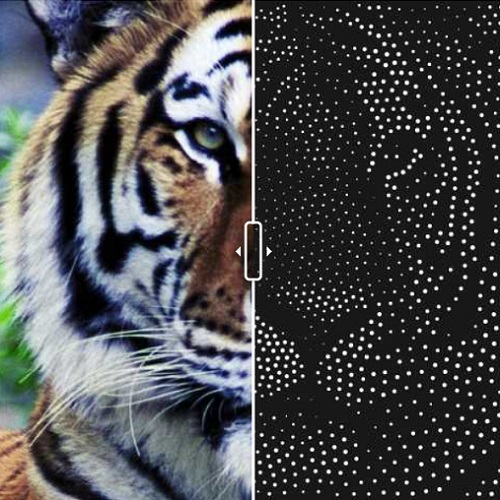

Picture Perforation

Pic Perf Sheet

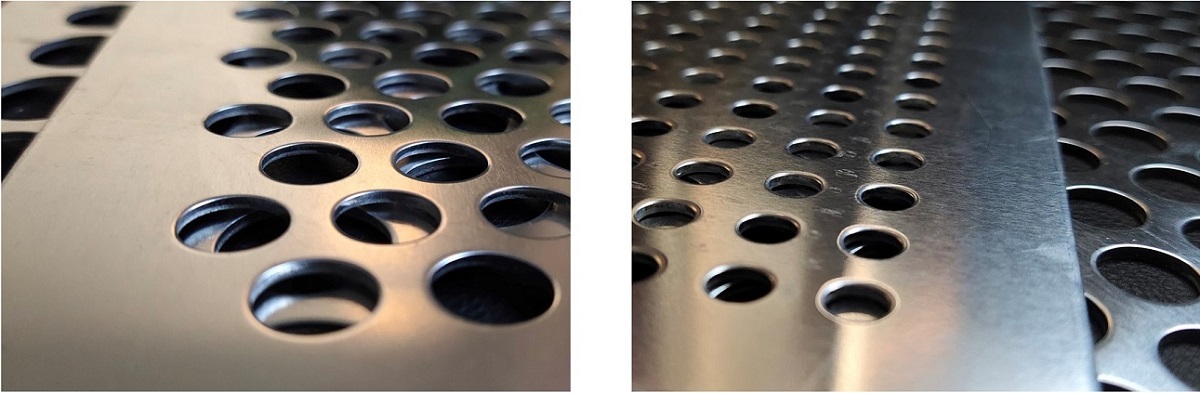

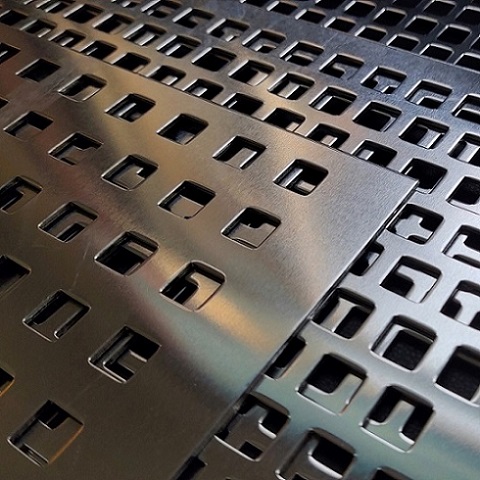

Square Hole Perforated Metal has two basic hole arrangements. One is paralleled holes pattern which is also called the straight pattern. The other one is the staggered pattern.

Square Hole Perforated Metal

Most Popular Material: AL Grade 3003, AL Grade 5052, Pre-Galvanized Steel Sheet.

Decorative Perforated Sheet

©COPYRIGHT METART BUILDING TEC CO., LTD | ALL RIGHTS RESERVED | PRIVACY POLICY