Material: Aluminium

Type: Rigid Security Screen Door Mesh

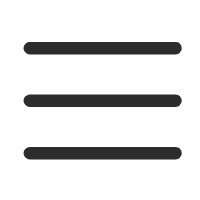

Thickness before powder coated: 1.6MM

Thickness after powder coated: 1.75-1.8MM

Standard Width: 750mm, 820mm, 900mm, 1200mm

Standard Length: 2000mm, 2200mm, 2400mm

Finish: Interpon Black Powder Coated, textured Finish and custom colors

GET A QUOTEWHAT IS PERFORATED ALUMINIUM SECURITY MESH?

Perforated aluminum security mesh represents a breakthrough in the security screen door infill panel industry. Crafted through a p recision punching process and enhanced with a high end powder coated finish, it stands as a remarkable innovation, particularly within the Australian market.

recision punching process and enhanced with a high end powder coated finish, it stands as a remarkable innovation, particularly within the Australian market.

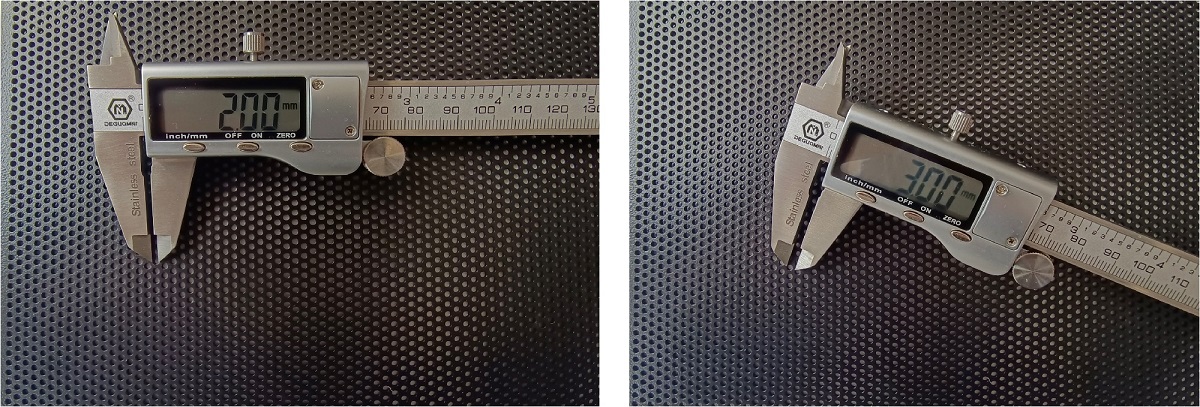

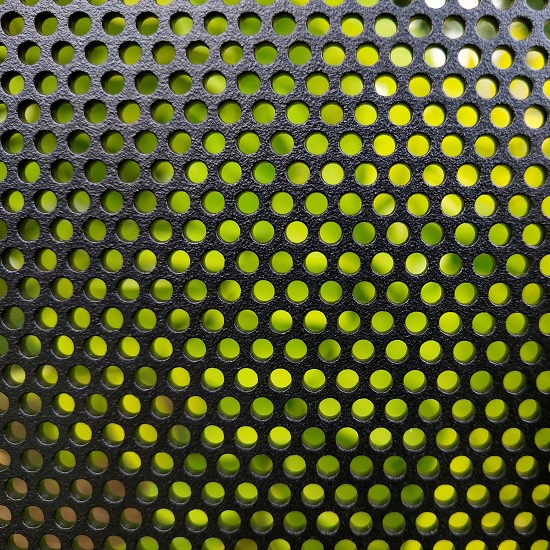

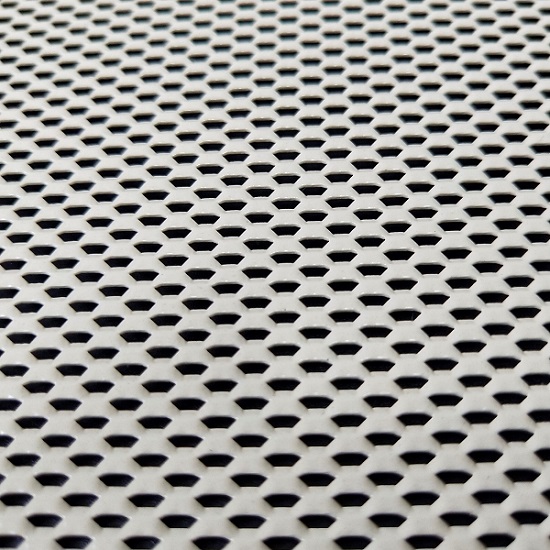

Distinguished by its classic 60-degree staggered round hole pattern, this cutting-edge security screen mesh offers both screen door fabricators and consumers an alternative that marries style with substance.

Unlike conventional diamond grille screen doors or security wire mesh options, this avant-garde solution boasts a flawlessly smooth surface and delivers a notably heightened level of privacy.

In addition to its aesthetic appeal, this perforated aluminum security mesh provides an exemplary blend of security and elegance, making it an exceptional choice for discerning individuals seeking to safeguard their homes without compromising on style or functionality.

Due to its enhanced security features, it has garnered promotion and endorsement from a few famous leading Australian companies like Alu-Gard Security Mesh and Xceed Screen Mesh.

WHO ARE WE AND WHAT WE CAN DO FOR YOU?

"Metart Building Tec" is a distinguished manufacturer specializing in wire mesh and perforated sheets, including industrial wire mesh, industrial perforated metal, and architectural wire mesh and perforated sheets. Our security screen window and door infill mesh series promoted as "Screen Tec," adheres rigorously to Australian standards. As a security mesh factory based in China, we are committed to supplying high-quality security door infill mesh panels.

We pride ourselves on delivering superior products that embody precision and quality. Our dedication to excellence makes us your trusted partner for all your security mesh needs.

HOW IS SECURITY PERFORATED ALUMINIUM MESH PRODUCED?

Here in this video we are showcasing the production process of our perforated aluminium security door panel, including perforation, powder coating, and packing.

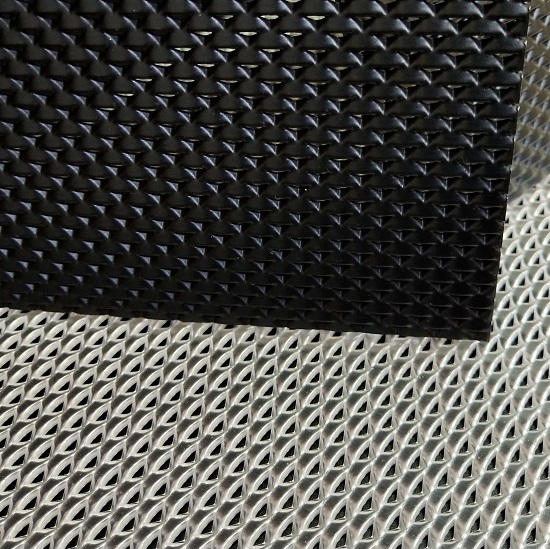

1.8MM Perforated Aluminium Security Mesh utilizes a 1.6mm solid aluminium sheet as its raw material which is then perforated and powder coated to outdoor grade. The material could be either regular 1 series aluminium sheets or marine grade 5052 aluminium sheets. The thickness will become approx 1.75mm to 1.8mm after the sheet is powder coated. Please note that there might be a tiny tolerance during production and measurement.

With a smooth surface and an outstanding staggered round holes appearance, perforated aluminum screen doors and windows are favored by a lot of architects and customers.

Compared to its stainless steel counterparts, perforated aluminium mesh offers a stronger structure to the screen doors and more privacy for customers' property but at a relatively lower cost.

Perforated Aluminium Sheet is well corrosion-resistant, even the regular 1 series aluminium is also corrosion-resistant to general environments, especially after it is powder coated with an extra outdoor grade layer, with the famous Interpon Series matte black powder from Akzo Nobel.

Not to say the marine grade 5052 aluminium plates, have even much better corrosion resistance properties and greater strength as well as excellent outdoor performance after they are powder coated.

EXPLANATION OF OUR PERF ALUMINIUM PATTERN CODE

By using this 1.6mm raw material, we offer two different hole sizes to meet different requirements in the market.

Pattern#:2030OA40 refers to a 2mm hole diameter with 3mm centers and a 40% opening rate, Therefore, people will get a 60% privacy rate. This pattern fully meets the Highest Bush Fire standard, which also makes it a perfect material for ember protective mesh. And it would be easier to keep the mosquitos and bugs out.

Pattern#:2337OA35, represents a Hole Diameter of 2.3mm, staggered pitch of 3.7mm, and Opening Area of 35%. This one is a commonly used one as it is a bit easier to produce.

HOLE SIZE OPTIONS:

►OPTION 1,

Pattern#: 2030OA40, Hole Diameter 2mm, Centers 3mm, Opening Area:40%.

►OPTION 2,

Pattern#: 2337OA35, Hole Diameter 2.3mm, Centers 3.7mm, Opening Area: 35%

MATERIAL OPTIONS

►AL 1060. The most affordable cost, with relatively good corrosion resistance, especially after being Interpon powder coated.

►AL 5052. Marine Grade Aluminium Grade, superior outdoor performance in marine environments, even better after being powder coated.

►Difference Between #2030OA40 and #2337OA35 Perforated Security Mesh 1.6MM

→Hole Diameter

Both meshes have different hole diameters. The #2030OA40 has a hole diameter of 2.0mm, which meets the highest standards of Australia's Bush Fire requirements. This makes it suitable for use as a bushfire ember protective screen mesh. The #2337OA35 has a larger hole diameter of 2.3mm.

→Staggered Pitch

The #2030OA40 has a smaller staggered pitch of 3.0mm, while the #2337OA35 has a larger staggered pitch of 3.7mm. A larger pitch reduces the opening area, limiting airflow and visibility, but it also increases the security of the mesh.

→Opening Area:

The #2030OA40 has a higher opening area of 40% compared to the #2337OA35, which has an opening area of 35%. The #2030OA40 Aluminium Perforated Screen offers a similar opening area to an 11Meshx0.8mm stainless steel security wire mesh. While the stainless steel mesh has an opening area of 42%, the #2030OA40 has an approximate opening area of 40%. This makes the #2030OA40 a viable and simplified alternative for security screen infill needs, striking a balance between security and other factors such as ventilation, visual appeal, insect protection, and visibility.

→Ventilation and Bug Protection

The #2030OA40, with its smaller hole diameter, provides more effective protection against small bugs or insects compared to the #2337OA35. Additionally, the higher opening area of the #2030OA40 allows for better ventilation.

→Different Adaptations of Thickness

The #2030OA40 perforated security mesh is specifically designed for use with 1.6mm aluminium perforated sheets, providing optimal performance and security. It is not recommended for use with 1.8mm aluminium perforated sheets. On the other hand, the #2337OA35 perforated security mesh offers more flexibility as it can be achieved on both 1.6mm and 1.8mm aluminium perforated sheets. This versatility allows you to choose the desired sheet thickness while maintaining the desired specifications of the #2337OA35, including the 2.3mm hole diameter, 3.7mm staggered pitch, and 35% opening area. Whether you opt for a 1.6mm or 1.8mm thickness, the #2337OA35 ensures consistent perforation characteristics for an appropriate balance of security, visibility, and airflow in your application.

►Standard Sheet Size

750 x 2000MM / 750 x 2200MM / 750 x 2400MM

820 x 2000MM / 820 x 2200MM / 820 x 2400MM

900 x 2000MM / 900 x 2200MM / 900 x 2400MM

1200 x 2000MM / 1200 x 2200MM / 1200 x 2400MM

Custom sizes are accepted.

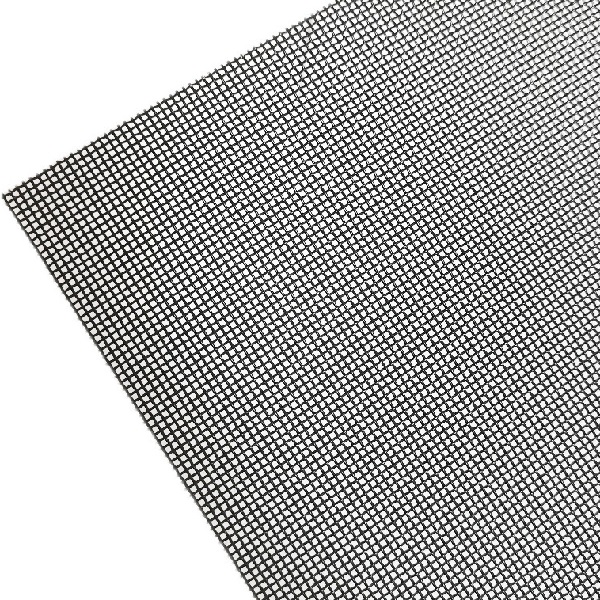

►Related Tests by AZUMA DESIGN

Knife Shear Test: PASS

.jpg)

.jpg)

Salt Spray Test: Pass ( 480Hours, Twice the required 240hours standard )

.jpg)

.jpg)

Bush Fire Grade: Meet with the highest BAL grade.

Marine Grade Stainless Steel Woven Wire 12Mesh x 0.7mm, Interpon Black Power Coated.

12Mesh 316 Stainless Steel Barrier Mesh

Black Powder Coated Stainless Steel Wire Mesh Mesh11x11, Dia.0.8mm

11Mesh 316 Stainless Steel Barrier Wire Mesh

Australian Standard Security Wire Mesh Manufacturer

Stainless Steel Security Wire Mesh

Perf-Guard Security Mesh, Alu-Guard Security Mesh

2.0MM Perforated Aluminium Security Mesh

Aluminium Light DVA Mesh 0.5mm thickness.

Aluminium Light DVA Mesh

Privacy aluminium mesh for security screen door 2.0 or 1.4mm thick optional

Heavy DVA Privacy Aluminium Security Mesh

©COPYRIGHT METART BUILDING TEC CO., LTD | ALL RIGHTS RESERVED | PRIVACY POLICY