Material: Stainless Steel 304 and 316L plates, Copper plates, Titanium plate

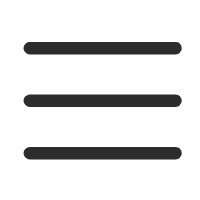

Type: Chemical etching micro hole metal screen

Regular Hole Diameter: 0.2mm to 2mm and even bigger custom-made diameter

Regular Thickness: 0.1mm to 0.9mm (up to 1.5mm)

Hole Diameter: Custom-made

Size: Maxinum500x600mm

Finish: Mill finish

GET A QUOTEEtching mesh is always referred to as an etched screen, etching perforated metal, or photochemical perforated screen.

This screen mesh is generally made of a very thin metal plate with extremely tiny holes smaller than 2mm in diameter. This process can be done with different raw materials including stainless steel sheets, copper and copper alloy sheets, titanium sheets, aluminum sheets, etc.

METART mainly produces stainless steel etched screens and parts including ss304 and ss316L, copper alloy etched screens, and a little bit of titanium etched mesh screens based on availability.

METART mainly produces stainless steel etched screens and parts including ss304 and ss316L, copper alloy etched screens, and a little bit of titanium etched mesh screens based on availability.

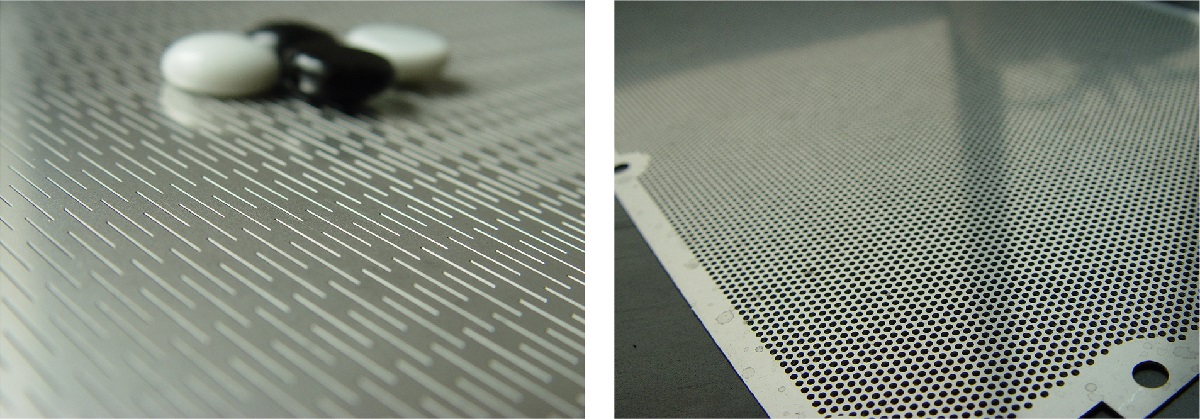

The aperture can be either a standard circular hole or other versatile exotic hole shapes. These holes are made into a very precise measurement. That is the reason this mesh plate is always called precision etching mesh.

Unlike mechanically punched metal sheets, this etched screen plate is produced in a totally different technology which is called chemical photo etching or photochemical machining.

This photo etching process involves a light-sensitive material named photoresist being applied to a pre-cut thin metal sheet using a CAD-designed photo stencil.

This photo stencil also known as a photo tool is then laminated onto the metal plate and then exposed to ultraviolet light.

The area that is covered by the photoresist will block the light and stay well.

Otherwise, the unmasked area of the metal plate will be etched and removed precisely from the sheet by acid solutions.

Photochemical etching technology offers a faster and more cost-effective alternative to mechanical punching, stamping, and laser cutting. It achieves intricate component pattern designs that cannot be done in regular mechanical ways with a way precise measurements.

Features of photochemical etched metal screens

-Smooth cut-out edges

-Burs-free holes

-Flat surface without any distortion as there is no mechanical stress is forced during the process.

-Cost-effective tooling.

-Beautiful outlook

-Intricate cut-outs supportive.

-Lowest tooling fee and sample production cost.

-Lowest MOQ

-Quick lead time

The production process of photoetched micro hole screen

Cad Drawing Preparation – A cad drawing is required for complex patterns. For simple round hole patterns, we can work out a CAD drawing based on your details description of hole diameter, centers, and margin sizes.

Photo tooling – Convert the current CAD drawing into a proper version and print it onto a photographic film. This process is called photo tooling. Based on the different sizes of the parts

Metal Sheet Preparation – Cut-to-size metal sheets will be prepared based on the size of the photo stencils. Make sure all the metal sheets are thoroughly cleaned and well-degreased.

UV Exposing – Using photo stencils, the ultraviolet lamps will expose the image of the product onto the photoresist coating. The well-prepared metal sheets are coated on both sides with UV light-sensitive and corrosion-resistant polymer. The coated metal plate is then laminated in between the top and bottom layers of the photo stencils.

Developing –The unexposed coatings are washed away and then a protective mask in the shape of the final parts will be formed. The unnecessary material that needs to be etched and removed away will be left uncoated.

Chemical Etching – Those uncoated areas of metal will be etched away, leaving the precisely made details of the components.

Stripping – The remaining coating of the parts will be cleaned with a special alkaline solution.

Inspection – A strict final inspection will be carried out after the parts are taken off the metal sheet to ensure it meets customers’ requirements.

Applications of precision-etched screens

-Industrial filter screens, Micro filters. commercial coffee machine screens, pour-over coffee filters

-Bespoke loudspeaker mesh grilles, earphone metal grilles.

-Food and beverage screens.

-EMI/RFI Shielding screen

-Flat Springs

-Connectors

-lighting diffusers

-Circuit board

Micro hole perforated stainless steel mesh filter cylinders

Precision Etching Micro Hole Perforated Stainless Steel Cylinders

Dutch Weave Stainless Steel Woven Wire Mesh Filter Cylinders

Dutch Weave SS Wire Mesh Filter Cylinders

Custom Made Rimmed Wire Mesh Discs.

Rimmed Wire Mesh Filter Discs

Brass Woven Wire Mesh & Brass Woven Wire Cloth

Brass Wire Mesh / Brass Wire Cloth

Square Hole Perforated Metal has two basic hole arrangements. One is paralleled holes pattern which is also called the straight pattern. The other one is the staggered pattern.

Square Hole Perforated Metal

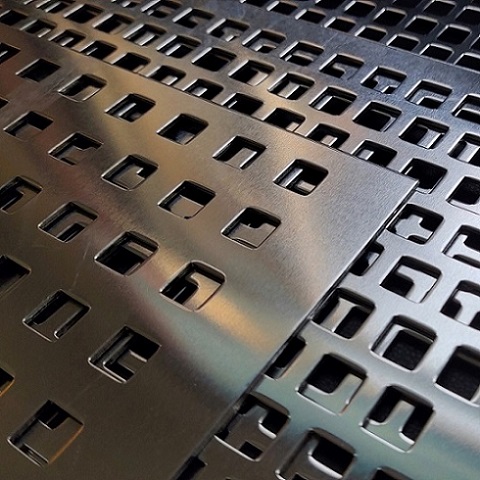

Perforated Sheets are also known as perforated metal, perforated plates, perforated mesh, punched sheets, punched metal mesh,

Standard Round Hole Perforated Sheets

©COPYRIGHT METART BUILDING TEC CO., LTD | ALL RIGHTS RESERVED | PRIVACY POLICY