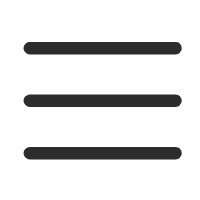

Material: Steel, Stainless Steel, Aluminum, Super Alloy, Copper, Brass, Bronze

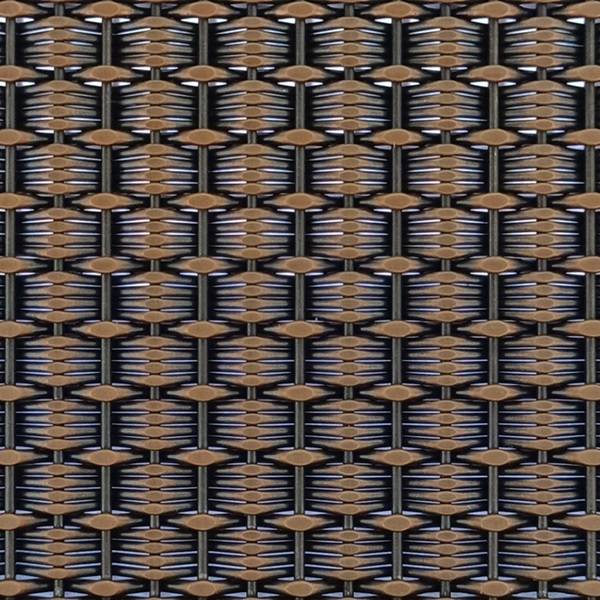

Type: Precrimped Woven Wire

Weaving Type: Double Crimp, Inter Crimp, Flat top, Lock crimped

Wire Diameter: Custom made

Opening Size: Custom made

Width: Custom made, up to 4000MM

Length: Custom made up to 6000MM

GET A QUOTE

Crimped wire mesh is one of the popular varieties of woven wire mesh, which involves a metal mesh made from wires that were crimped in advance. The need for  such a type of wire mesh arises when the required diameter of the wire exceeds standard loom capabilities for weaving or when opening size requirements surpass those that can be accommodated by the regular weaving process as a result of the diameter being too small. As a result, the technique of crimping was developed to improve the hardness and stiffness of metallic wires. And these panels are precisely woven, maintaining an opening size relatively accurate enough. At the same time, all these wires stay within their crimps without any slackening or movement at all. Some pre-crimping patterns have been developed to cater to specific market needs, including the mining industry, fencing projects, filtration, interior cladding, and architectural decoration.

such a type of wire mesh arises when the required diameter of the wire exceeds standard loom capabilities for weaving or when opening size requirements surpass those that can be accommodated by the regular weaving process as a result of the diameter being too small. As a result, the technique of crimping was developed to improve the hardness and stiffness of metallic wires. And these panels are precisely woven, maintaining an opening size relatively accurate enough. At the same time, all these wires stay within their crimps without any slackening or movement at all. Some pre-crimping patterns have been developed to cater to specific market needs, including the mining industry, fencing projects, filtration, interior cladding, and architectural decoration.

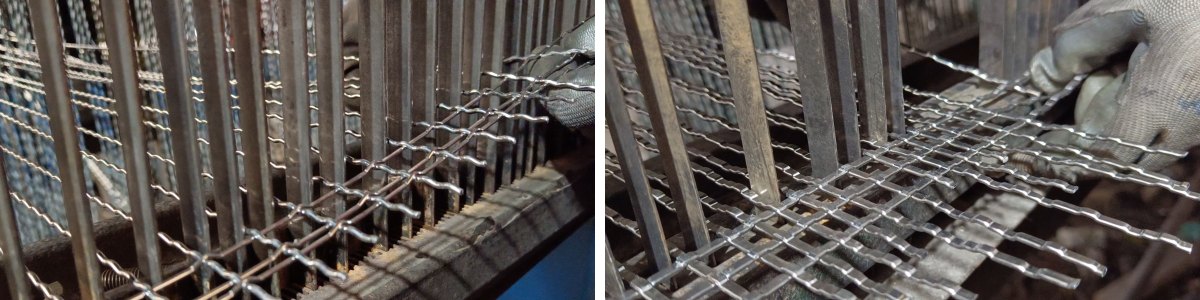

DISCOVER THE PROCESS OF MANUFACTURING CRIMPED WIRE MESH

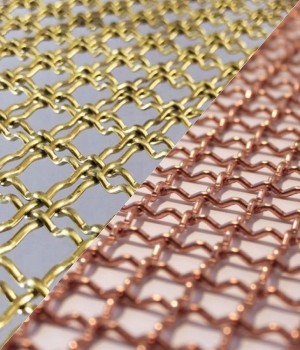

Tooling Making:

For c rimping purposes, tooling usually includes two steel wheels built from special hardened alloy capable of withstanding continuous crimping processes. These are machined and cut by wire EDM machines based on different wire gauges, opening sizes, and designs for crimping. Manufacturers frequently prepare several pairs at a time to expedite production.

rimping purposes, tooling usually includes two steel wheels built from special hardened alloy capable of withstanding continuous crimping processes. These are machined and cut by wire EDM machines based on different wire gauges, opening sizes, and designs for crimping. Manufacturers frequently prepare several pairs at a time to expedite production.

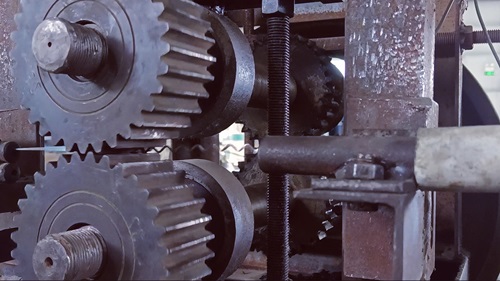

Wire Crimping:

Before production starts, the wire has to be pre-cut into the desired size needed for making the wire mesh.

The warp wire is longer than the weft one hence crimping has to be done separately against other preparations. They then pa ss through running alloy wheels having customized crimps fitted on them after which they emerge with them as shown before this happens throughout this procedure adequate lubricating should be done on it to prevent incidences like scratches or damage once its length reaches its specified length then this is where ceasing of crimping takes place and the wire is cut off.

ss through running alloy wheels having customized crimps fitted on them after which they emerge with them as shown before this happens throughout this procedure adequate lubricating should be done on it to prevent incidences like scratches or damage once its length reaches its specified length then this is where ceasing of crimping takes place and the wire is cut off.

Warping and Threading:

After pre-crimping, the warp wires are either passed through a warping process for automatic looms or they are taken to the back side of machines for threading in the case of semi-automatic looms. This will make sure that warps are passed through heddles and weaving reed to be positioned correctly.

Weaving: In some cases, weft wires can either be picked up automatically by a band gripper or fed into the warp wires manually by an operative. The choice of machine depends on wire diameter as well as wire mesh specifications.

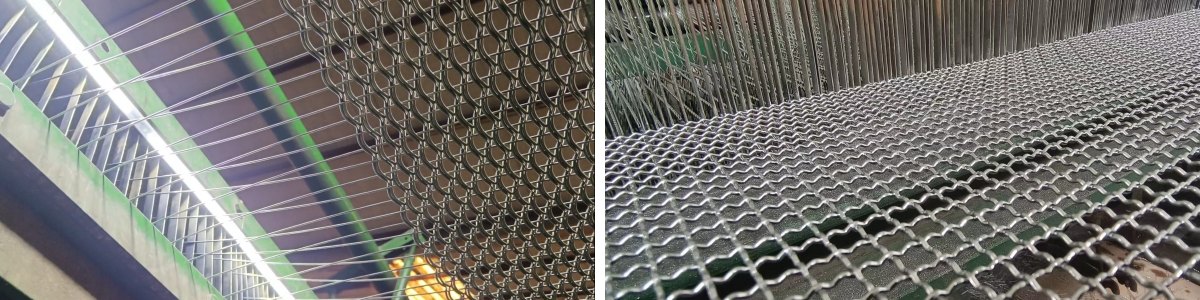

MAJOR WEAVING PATTERNS OF CRIMPED WIRE MESH

Double Crimped Pattern: Although this pattern appears almost similar to plain weave woven wires, it closely looks like a plain weave crimped pattern. The single difference is that double-crimped mesh is already crimped before the insertion of weft wires while regular plain weave takes place inside the loom with crimps being created naturally by the steel weaving reed sitting on the sley at each beat.

Intermediate Crimped Pattern includes a continuous series of multi-crimps that improve panel strength and wire rigidity while giving them a touch of elegance.

Lock Crimp Pattern: This pattern is widely used for heavy-duty sieving and screening applications which enhance screen stability and overall strength, making it ideal for architectural and design purposes as decorative cladding materials in buildings.

Flat Top Crimp Pattern: There is a different appearance on both sides of this unique pattern on wire mesh. One side has got crimps while; the other has no such roughness but a smooth surface hence minimizing friction during screening operations. It has also turned out to be popular with architects and designers in use in quarrying wire mesh; mining screens; as well as architectural applications.

Complex Decorative Crimping: These complicated crimped designs involve developing personalized patterns through customers’ drawings, sketches, and tangible samples. This process enables customized developments to be designed specifically for individual preferences and customer requests concerning the projects and requirements. It is a unique way of incorporating art into different applications, ensuring that each item is exceptional as well as satisfying special demands.

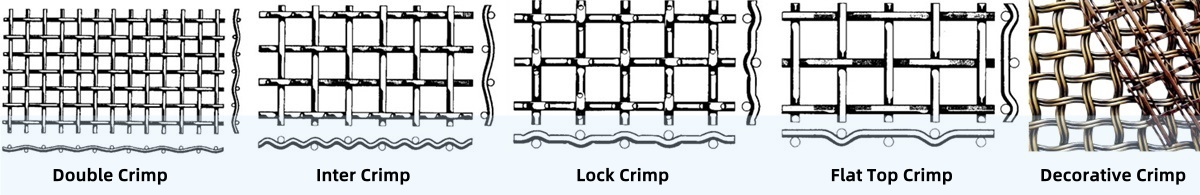

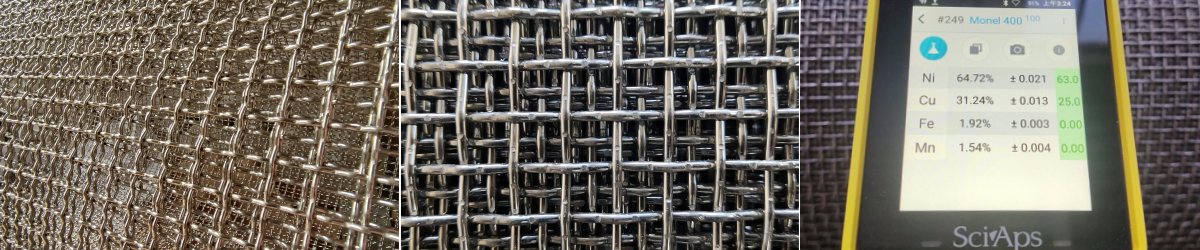

AVAILABLE MATERIALS FOR MANUFACTURING CRIMPED WIRE MESH

Iron Steel: The most cost effective wire mesh alternative commonly used in agricultural fields and industrial filtration processes.

Manganese Steel: Notable for its toughness with 65Mn crimp steel mesh is found mostly in mines and quarries.

Galvanized Steel: Present in pre-hot dip and pre-electro galvanized forms, hot dip has better resistance to corrosion than standard steel mesh making it a superior substitute to common steel wire mesh.

Stainless Steel: The most commonly used material for crimped screen mesh with grade 304 being the regular stock size. Other possible options include grades like 316,316L,321, and 310 among others as per demand. Stainless steel crimped woven wires are popularly employed both in industry and architectural applications.

Nickel-Based Super Alloys: Nickel-based superalloys consist of materials such as Inconel, Incoloy, Hastelloy, and pure nickel among others refined to make strong, resistant-to-corrosion types of crimped meshes that are capable of working at high temperatures. These alloys provide reliable solutions whether for tough industrial situations or particular circumstances that call for top performance. They are utilized in industries that cannot compromise on reliability and durability including aerospace, chemical processing, and marine engineering since they must have the utmost dependability.

Copper, Brass & Bronze: Known for their excellent conductivity properties, making them attractive alloy choices across various industries. in architecture, these metals are sought after due to their unique natural colors, which do not exist anywhere else except themselves.

Metart Building Tech: Innovating Crimped Wire Mesh Production for Contemporary Architecture

Along with serving functional purposes, crimped wire mesh has become a material of choice for weaving together innovation, aesthetics, and tremendous strength in the world of architecture, industry, and interiors. Crimped wire mesh is a functional component that has evolved into a feature that defines and shapes the aesthetics and the architecture of a space. This remarkable change is driven by Metart Building Tech—an industry-leading manufacturer of high-performance crimped wire mesh.

From sleek architectural graded facades to industrial filtration systems, Metart Building Tech promises unrivaled quality, precision, and versatility. Steeped in craftsmanship and fueled by innovation, the company sets a new standard with Metart Building Tech wire mesh products that are both decorated and stunningly beautiful, while being functionally unparalleled.

What is Crimped wire mesh?

Crimped wire mesh is a woven wire fabric processed with corrosion-resistant metal wires, especially made of stainless steel wires. Its wide range of applications includes security screening, filtration, structural reinforcement, and architectural features.

Withstanding corrosion, stainless steel's durability, fire resistance, and strength-to-weight ratio make it essential in various industries. Crimped stainless steel wire mesh delivers durable, corrosion-resistant performance—used for façade screens and railing infills in high-rise buildings, and for long-life filtration and screening in processing plants.

Metart Building Tech: Crafting Excellence in Every Strand

Metart Building Tech's integration of deep engineering and architectural design sets them apart. They have earned considerable trust in the crimped wire mesh industry as one of the most advanced manufacturers with customization technologies that cater to the client's needs, delivering extraordinary solutions.

▸ Architectural Woven Wire Mesh

Metart Building Tech: architectural woven wire mesh emphasizes transparency alongside textural depth without compromising on the structural elegance. Made from top-grade SS304, SS316, and SS316L stainless steel, these meshes offer excellence in weather resistance, corrosion, and aging.

Common applications include:

• Building facades & sunshades

• Balustrades & stair enclosures

• Wall claddings & column wraps

• Interior partitions & ceiling panels

Every mesh pattern is specifically designed to maintain the equilibrium of light and air filtration, privacy, and elegance, thereby allowing the architects to have freedom with their ideas.

▸High-Precision Stainless Steel Sieving Mesh

Similarly, Metart produces stainless steel sieving mesh for industrial and technical purposes. This type of mesh is great for:

- Filtration and Separation Systems

- Screening and Sieving

- Food and Pharmaceutical Industrial Processing

- Petrochemical and Mining Industries

Metart’s stainless steel wire cloth offers different mesh sizes and weaving styles. The wire cloth is produced with tight tolerances and consistent stainless steel wire cloth mesh quality, ensuring accuracy and dependability for critical operations.

Core Benefits of Using Metart’s Crimped Wire Mesh Solutions

✅ Superior Corrosion Resistance

Made from high-grade stainless steel, METART crimped woven wire mesh products offer excellent resistance to corrosion and oxidation, making them ideal for outdoor applications and harsh industrial environments.

✅ Tailor-Made Fabrication

Every project is different. Metart works with the project architects, the designer, and the engineer to create custom wire mesh products tailored to the project’s specifications. Tailor-Made options comprise mesh dimensions and weave pattern, frame and surface finishes, and more.

✅ Design-Driven Engineering

With Metart’s architectural mesh, they do not sacrifice aesthetics for functionality. Their products increase the appeal of commercial, hospitality, and cultural buildings while serving as passive climate control and security.

✅ Sustainability First

The recycling of stainless steel makes it a sustainable material for designing products. Metart's eco-friendly processes match green global manufacturing benchmarks, contributing to certifications like LEED, thus decreasing environmental impact.

Where Metart Crimped Wire Mesh Makes a Difference?

Metart Building Tech’s wire mesh products aim to serve multiple industry needs as crimped wire mesh:

➤ In Architecture

Exterior cladding and sunscreens

Decorative curtain walls

Safety balustrades and guardrails

Feature walls and ceilings

➤ In Industry

Chemical and oil filtration

Water treatment filtration

Mechanical sieving and sorting

Dust and particle filtration

➤ In Design

Room and privacy dividers

Tailored light fixtures

Meters of acoustic mesh for sound control

Art and branding feature installations

Precision, Innovation, and Trust

With Metart, every product goes through validation and international compliance checks, undergoing strict quality control. They have modern weaving and cutting machines manned by skilled operators who ensure accuracy and uniformity.

Metart’s solution extends beyond product delivery. They give comprehensive assistance, including consulting, design modification, prototype sampling, and swift shipping to any country. We aim to give designers, builders, and engineers materials that are inspiring and enduring, hence empowering them.

Why Metart Building Tech Is the Manufacturer of Choice?

Here are some of the reasons that make Metart Building Tech a go-to for leading architectural firms, industrial purchasers, and construction companies when it comes to wire mesh in stainless steel:

• Decades of industry experience

• Worldwide project exposure

• Fully customizable products

• Short deadlines and fast response times

Affordable rates, while still maintaining strong standards for quality

Metart Building Tech's unparalleled crimped wire mesh products help industry professionals source material, whether it’s for a landmark architectural project or a precision filtration system.

Conclusion: Strategic Manufacturer Decisions for the Endless Possibilities of Crimped Wire Mesh

The continuous evolution of crimped wire mesh and architectural interfaces expands new industrial and architectural possibilities—making the decision of manufacturer's choice of key strategic importance. With Metart Building Tech, one does not only get wire mesh, but rather a manufacturer and partner that stands for unwavering quality, innovation, and vision.

A Metart Building Mesh architectural wire stainless steel facade highlights the modern design of the building, while the industrial mesh components support its critical functions. Thus, Metart is continuously shaping the future with crimped wire mesh, one wire at a time and one weave at a time, one masterpiece at a time.

Metart Building Tech is where engineering marries artistry in stainless steel.

Decorative Metals for Designers and Architects

Designer Metals for Interior Cladding and Decoration including elevator cabin & lobby interiors

Plain Weave Stainless Steel Wire Mesh

Plain Weave Stainless Steel Wire Mesh

welded wire mesh in stock and custom made

Stainless Steel Welded Wire Mesh

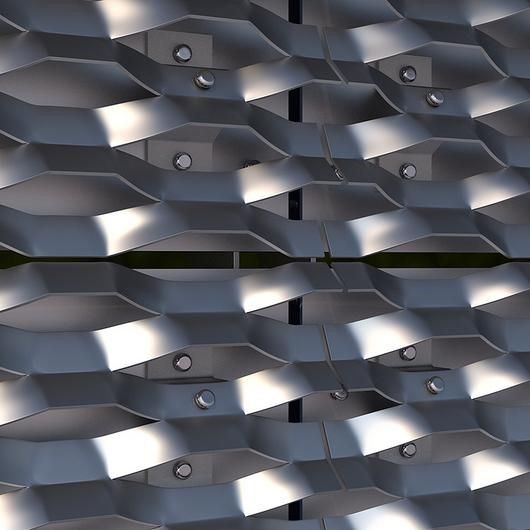

Expanded Metal Sheet is a three-dimensional sheet metal mesh that is firstly cut and then quickly stretched to form repeated diamond-shaped hole patterns.

Architectural Expanded Metal

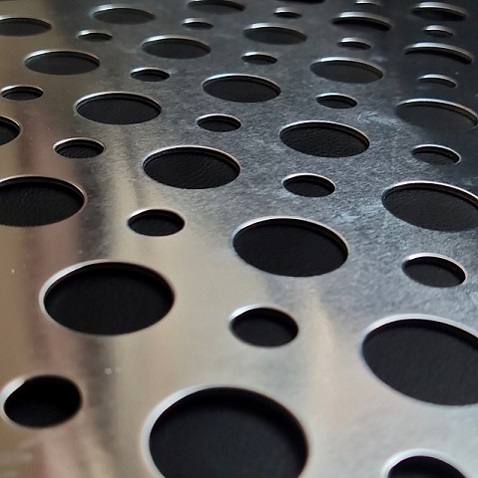

Most Popular Material: AL Grade 3003, AL Grade 5052, Pre-Galvanized Steel Sheet.

Decorative Perforated Sheet

Antique Brass Plated Divider Mesh Strip 2.2x1.2mm, Wire Diameter 1.5mm

Antique Brass Plated Architectural Mesh for Room Dividers and Partitions - METART-WW26B-

©COPYRIGHT METART BUILDING TEC CO., LTD | ALL RIGHTS RESERVED | PRIVACY POLICY