Post time: 08 25,2025

Metart Building Tech has distinguished itself in architectural metal solutions by offering the industry’s highest quality perforated sheets, leading the market in offering showers of innovation by meeting the demands of design accuracy, long-lasting strength, easy modifications, and unparalleled precision in the metal sheets' perforation.

What Are Perforated Panels and What Distinguishes Them?

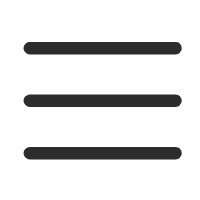

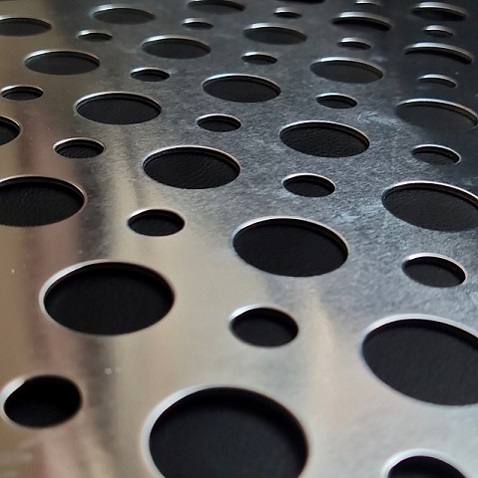

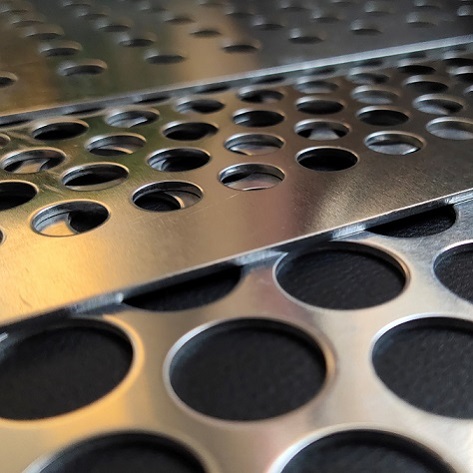

As the name suggests, perforated metal sheets are metal sheets with a series of holes, slots, or decorative shapes punched or stamped into them. Depending on the design intent, holes can be staggered, decorative, or fully customized. In addition, perforations can be functional or aesthetic.

Utilized metals include stainless steel, aluminum, mild steel, galvanized steel, and brass, and as all these metals are available in a wide range of thicknesses, finishes, and perforation patterns, mild steel becomes a viable option. Moreover, Metart Building Tech offers precision-engineered perforated sheets. For long-term use in harsh conditions, they ensure Consistent hole sizes, flawless edge quality, and, differentiating them further, corrosion-resistant finishes.

Applications Across Industries

Due to its versatility, perforated metal panels have found use in different industries, including:

1. Architectural Facades

Architects routinely design with Perforated panels to create shading, texture modification, as well as visual interest for building exteriors. Throughput significantly, reduce solar gain while allowing natural light, which is a hallmark of energy efficient design. For custom perforated architectural designed façades, visit Metart Building Tech for tailored solutions.

2. As Features in Interiors

As feature walls and ceiling panels, perforated metals elevate the interiors of a building. Because of the balance to airflow and visual access, they work well for room dividers, stair railings, as well as decorative privacy screens.

3. Sunshades and Louvers

Panels with holes in them are ideal for shading systems that reduce glare as well as heat, while enabling light penetration. Metart Building Tech makes sunshades that are effective in improving comfort and energy efficiency for both homes and commercial buildings.

4. Acoustic Panels

Used with sound-absorbing materials, perforated sheets are effective as acoustic panels used in auditoriums, offices, and even industrial offices. Besides serving its intended function, they help minimise noise pollution with design elegance.

5. Ventilation and Filtration

Perforated sheets have important applications in machine enclosures, air conditioning grills, and filter systems where air separation and controlled air flow are crucial. Metart Building Tech perforating technology guarantees both airflow and filtration efficiency.

6. Security and Screening

Perforated panels are widely used for fencing and machine guards as they provide security while maintaining visibility. In many applications, they are a more secure choice than mesh or glass due to their strength and adaptability.

Why Choose Perforated Metal Panels from Metart Building Tech?

There is a difference in quality among manufacturers. Metart Building Tech is known for:

Custom Design Capabilities – Specialized for each client, Metart Building Tech offers unique design options with tailored patterns as well as functional requirements.

Premium Material Selection – With trustworthy, high-quality, and corrosion-resistant metals, customers are provided with durability and strength over time.

Advanced Manufacturing Precision – Specialized machinery provides accurate and clean perforations that minimize waste.

Diverse Finishes – Options for polishing, anodizing, powder coating, and galvanizing.

Expert Consultation – The right thickness, patterns, and finishes are chosen from a variety of options, ensuring every design is unique.

This mix of technical skills and design insight guarantees that any Metart Building Tech perforated panel will undergo the appropriate scrutiny and pass the mold of the industry’s best practices.

Benefits of Perforated Metal Panels

1. Aesthetic Appeal

With the aid of skilled artisans, metal perforated panels can be made to bond with their background and can also be boldly used to make unapologetic statements that enhance their background. Panels can be geometric, floral, abstract or can even brandish logos of their clients.

2. Energy Efficiency

These panels control the sunlight and heat that penetrates the premises, hence assisting in the minimization of HVAC loads, thus helping to achieve energy-efficient building design goals, which can be of great aid in the holistic mitigation of carbon emissions.

3. Structural Strength with Reduced Weight

In addition, the stainless steel sheets and strips will be lighter relative to the solid sheets; thus, the perforated panels will be easier to handle and install.

4. Ventilation and Airflow

As is essential in other industries, air movement is vital in the food processing, automotive, and HVAC sectors. These perforated sheets enable air movement, thereby protecting them without the danger of breaching security.

5. Durability

With the proper finishing and with the use of corrosion resistant metals, perforated panels can be made to last for decades with little to no maintenance.

6. Sustainability

These panels can be incorporated within energy and environmentally friendly compliance and green building projects as the majority of metals used in the perforated panels can be recycled.

Design Flexibility with Metart Building Tech

With Metart Building Tech, you get to enjoy custom-made perforation designs which makes them stand out. This flexibility enables branding, thematic motifs, or functional specifications to be embedded right on the panels. From a corporate office to an industrial facility with a unique façade of ventilated design, Metart Building Tech custom makes panels to suit all design and manufacturing needs.

Quality Assurance and Industry Standards

Quality and precision of sections for Metart Building Tech constructions are critical, especially for architectural and industrial applications. With Metart Building Tech’s panels, clients receive custom, rigorous engineering panels that are internationally compliant to strength, accuracy, and longevity. Their adoption of advanced punching and laser-cutting technology to uphold industry standards for precision, sharpening the panels their products are manufactured with, enables them to earn a reputation for delivering tight tolerances, smooth edges, and consistent hole alignment on hefty production volumes.

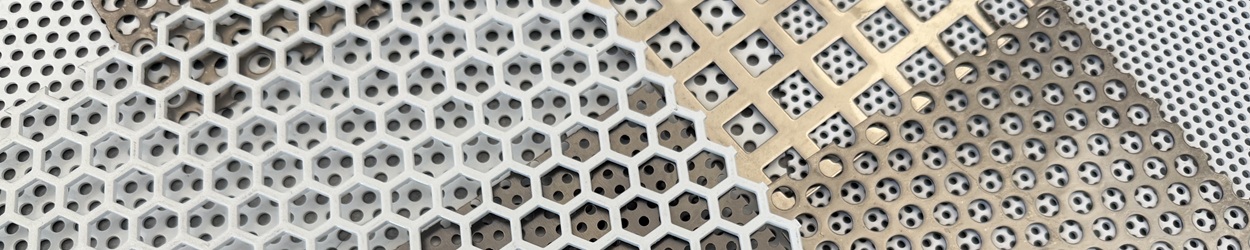

Integration with Other Architectural Metal Solutions

Architectural woven wire mesh and other metal clasps are other products that Metart Building Tech does not limit themselves to, as they offer a variety of differing products. Further, woven wire mesh does not limit to a single application. It combines with the perforated panels, which offer layered designs adding texture and depth, while being useful to be applied to interiors as well as in exteriors. With this, designers are more equipped with an integrated approach to the design metals for higher efficiency.

Conclusion

Beyond serving as mere design components, perforated metal panels integrate creativity, technology, and eco-consciousness. Their versatility and visual promise make them indispensable to contemporary construction and manufacturing. With proficiency in precision metalworking, manufacturing processes, and materials, as well as custom design, Metart Building Tech is trusted by architects, designers, and industrial clients for unparalleled quality in perforated sheet products and offers comprehensive support for unchecked creativity and design.

With Metart Building Tech, you invest in panels constructed to perfection with unrivaled durability, striking aesthetic, and functional performance with a promise that your design will achieve and outshine expectations.

Metal Lattice for Home Decor and DIY

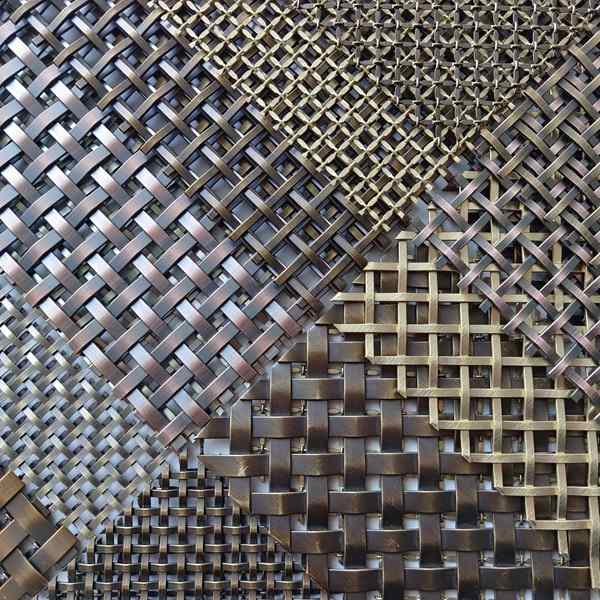

Slip Resistant Dimpled Hole Perforated Planks

Anti-Slip Perf Oo Planks with Drainage Hole

METART screens are widely been used both indoors and outdoors including interior wall arts, partition screens, decorative room dividers

Laser Cut Garden Screen / Laser Cut Wall Art

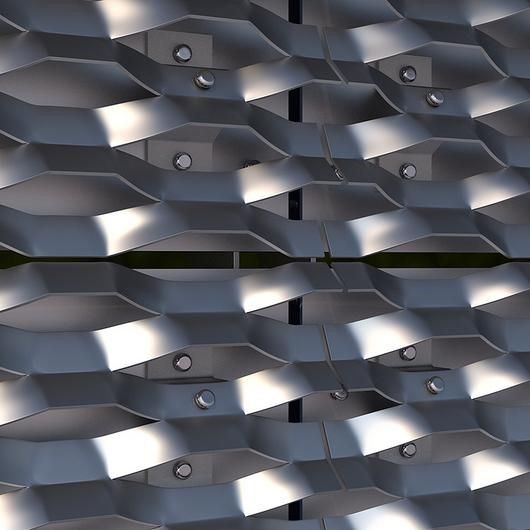

Expanded Metal Sheet is a three-dimensional sheet metal mesh that is firstly cut and then quickly stretched to form repeated diamond-shaped hole patterns.

Architectural Expanded Metal

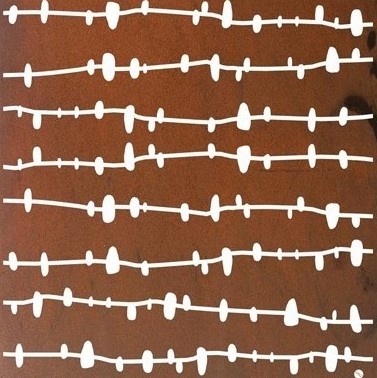

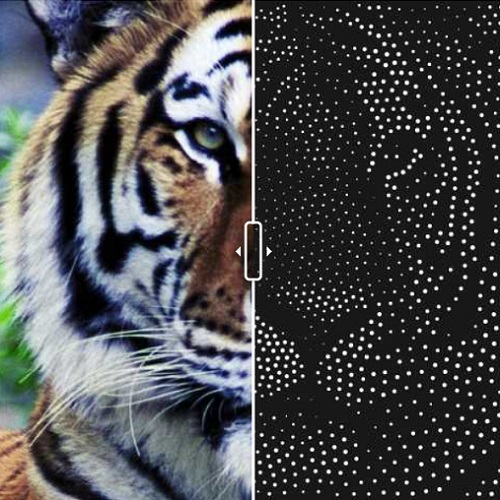

Picture Perforation

Pic Perf Sheet

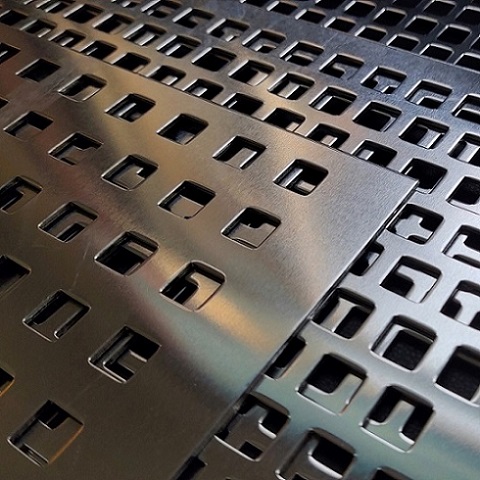

Square Hole Perforated Metal has two basic hole arrangements. One is paralleled holes pattern which is also called the straight pattern. The other one is the staggered pattern.

Square Hole Perforated Metal

Most Popular Material: AL Grade 3003, AL Grade 5052, Pre-Galvanized Steel Sheet.

Decorative Perforated Sheet

Perforated Sheets are also known as perforated metal, perforated plates, perforated mesh, punched sheets, punched metal mesh,

Standard Round Hole Perforated Sheets

©COPYRIGHT METART BUILDING TEC CO., LTD | ALL RIGHTS RESERVED | PRIVACY POLICY