Post time: 02 11,2023

Stainless Steel Grade 304 and Grade 321 are two of the most commonly used types of stainless steel in the industrial woven wire mesh and welded wire mesh industry.

Both of these two different materials have their unique properties, making them suitable for different applications.

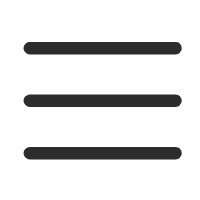

Chemical Compositions:

Stainless Steel 304 is well-known austenitic stainless steel that contains a high level of chromium and nickel, typically 18% chromium and 8% nickel.

On the other hand, Stainless Steel 321 Grade contains a higher amount of titanium, which is added to improve its high-temperature resistance. The addition of titanium helps to stabilize the steel, reducing the risk of intergranular corrosion.

|

Grade |

C % |

Si % |

Mn % |

Cr % |

Ni % |

S % |

P % |

N % |

Ti % |

|

304 |

0.08 |

1.0 |

2.0 |

18.0-20.0 |

8.0-10.5 |

0.03 |

0.045 |

/ |

/ |

|

321 |

0.08 |

1.0 |

2.0 |

17.0-19.0 |

9.0-12.0 |

0.03 |

0.045 |

0.1 |

5C-0.70 |

Corrosion Resistance:

Stainless Steel 304 is famous for its good corrosion resistance in a variety of environments. Wire meshes and wire clothes made of SS304 wires can withstand exposure to corrosive chemicals, salts, and acids. However, it is not as resistant to high-temperature oxidation and corrosion as wire meshes and clothes that are made of Stainless Steel 321 wires. The higher amount of titanium in Stainless Steel 321 provides it with improved resistance to high-temperature oxidation and corrosion, making it ideal for applications in high-heat environments.

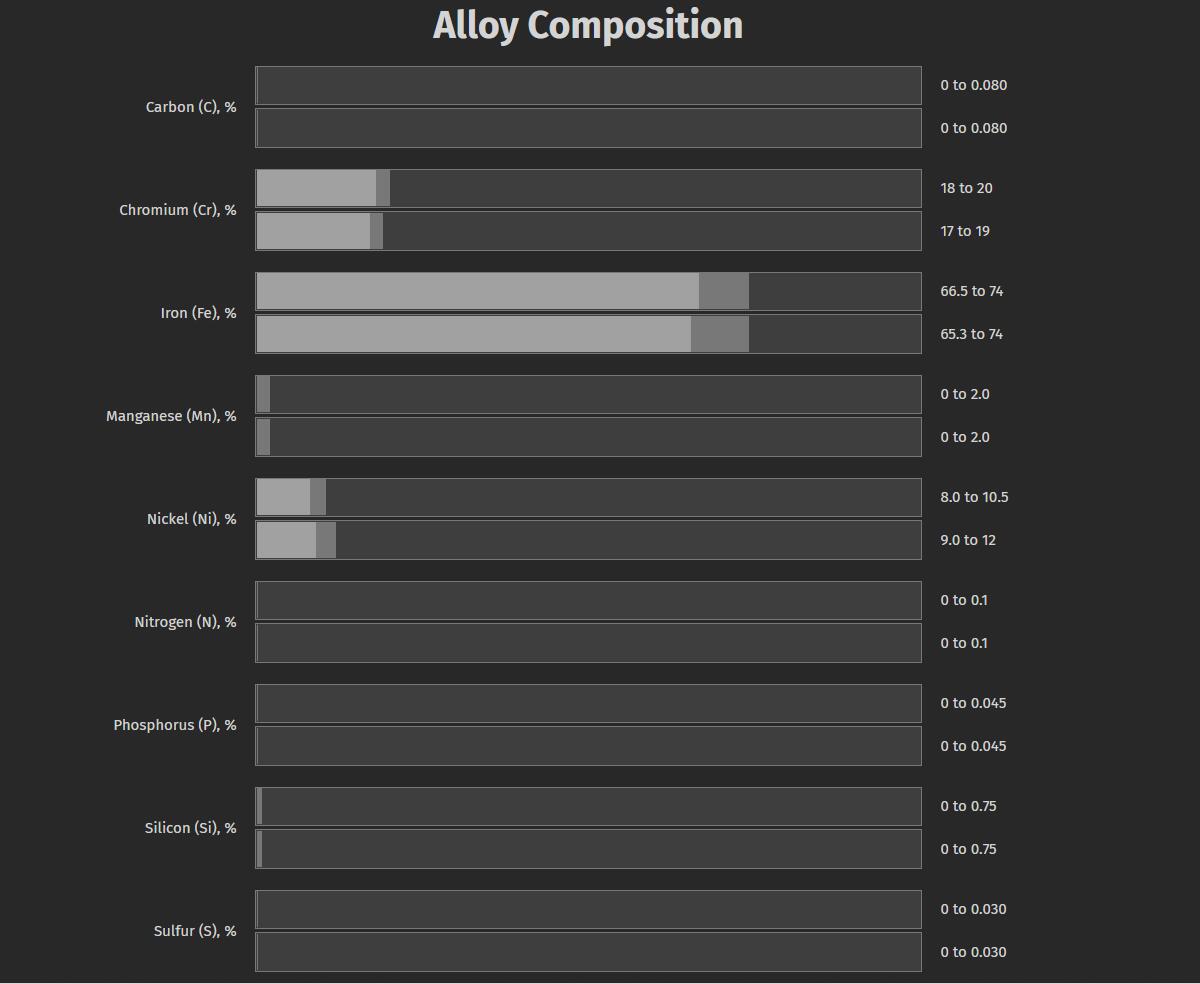

High-Temperature Properties:

One of the key differences between Stainless Steel 304 and Stainless Steel 321 wire mesh and wire clothes are their ability to withstand high temperatures.

Stainless Steel 321 is designed to withstand high temperatures and has a melting point of around 1500°C, making it ideal for high-heat applications. On the other hand, Stainless Steel 304 has a lower melting point of around 1400°C, making it less suitable for high-heat applications.

Based on this big difference, you should choose the wire mesh material carefully before you mapurchaseccording to your using environment.

Weldability:

Another difference between these two types of stainless steel is their weldability. Stainless Steel 304 is easier to weld compared to Stainless Steel 321, which can be more challenging to work with due to its high titanium content. The high titanium content can cause cracking during the welding process, making it important to use proper welding techniques and filler metals when welding Stainless Steel 321.

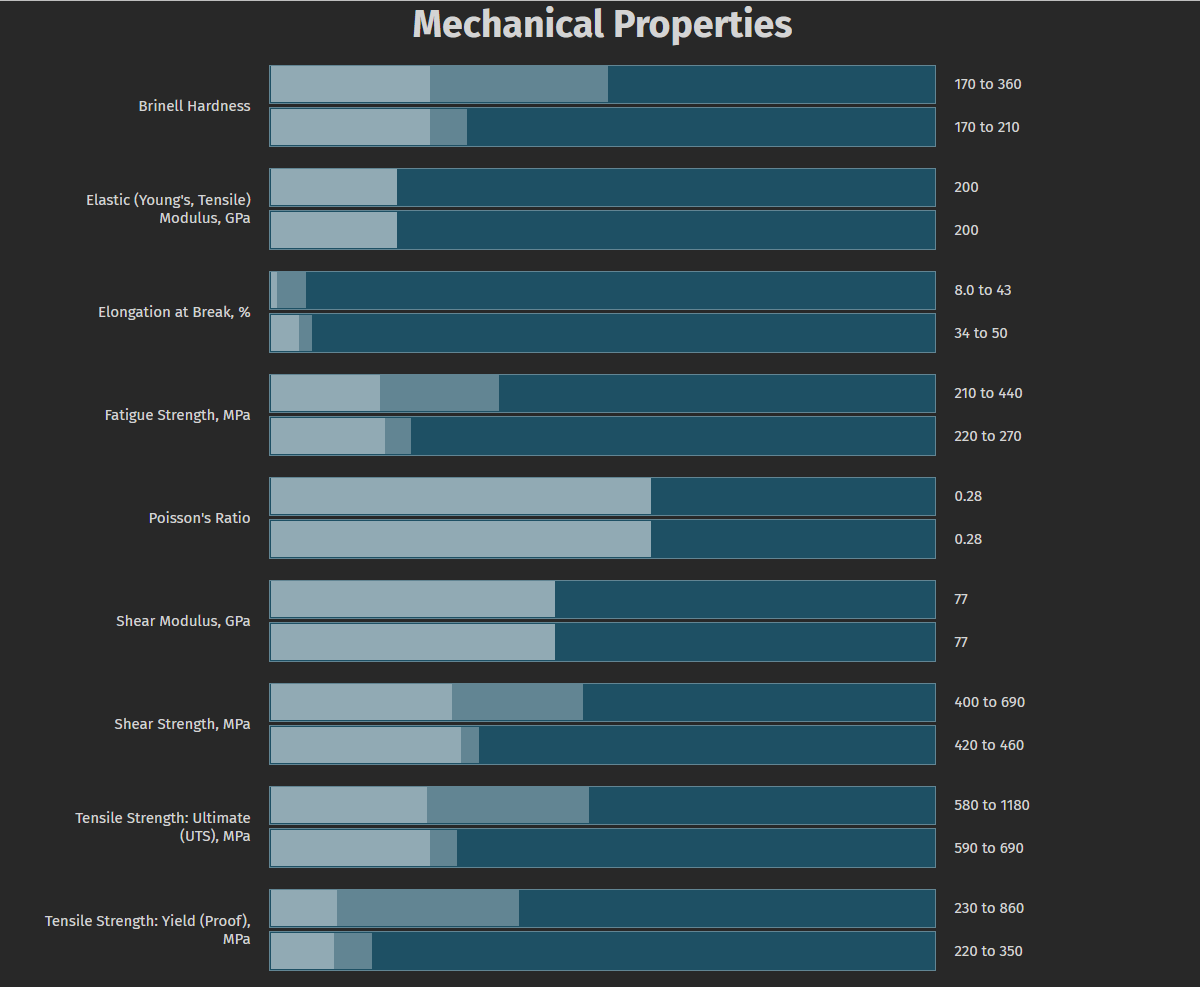

Mechanical properties:

The mechanical properties of stainless steel 304 and 321 wire mesh products can vary depending on factors such as the manufacturing process, heat treatment, and cold working. However, in general, these two materials have similar mechanical properties.

Tensile Strength:

Both stainless steel 304 and 321 have similar tensile strengths, with 304 having a tensile strength of 515 MPa and 321 having a tensile strength of 515-655 MPa. This high tensile strength makes these materials suitable for applications that require high levels of strength and durability.

Yield Strength:

The yield strength of stainless steel 304 is 205 MPa, while the yield strength of stainless steel 321 is 205-450 MPa. The higher yield strength of 321 makes it more suitable for applications that require high levels of strength under stress.

Elongation:

The elongation of stainless steel 304 is 40%, while the elongation of stainless steel 321 is 40-45%. The high elongation of these materials makes them more suitable for applications that require high levels of ductility.

Hardness:

The hardness of stainless steel 304 is typically in the range of 180-200 HB, while the hardness of stainless steel 321 is typically in the range of 180-200 HB. The similar hardness of these materials makes them suitable for applications that require good wear resistance.

In conclusion, both Stainless Steel 304 and Stainless Steel 321 have their unique properties that make them suitable for different applications. Stainless Steel 304 woven mesh and welded wires are versatile and commonly used materials that offer good corrosion resistance, while Stainless Steel 321 screen mesh is designed to offer improved high-temperature resistance and oxidation resistance.

The choice between these two filter wire mesh materials will depend on the specific requirements of your application. If you need wire mesh that can withstand high temperatures and has good resistance to oxidation and corrosion, Stainless Steel 321 may be the best choice. On the other hand, if you need wire mesh that is versatile and offers good corrosion resistance in low to moderate-temperature environments, Stainless Steel 304 may be the right choice.

If you are not sure which material is suitable, It is always necessary to consult with a material expert or a material supplier to determine the best option for your specific application.

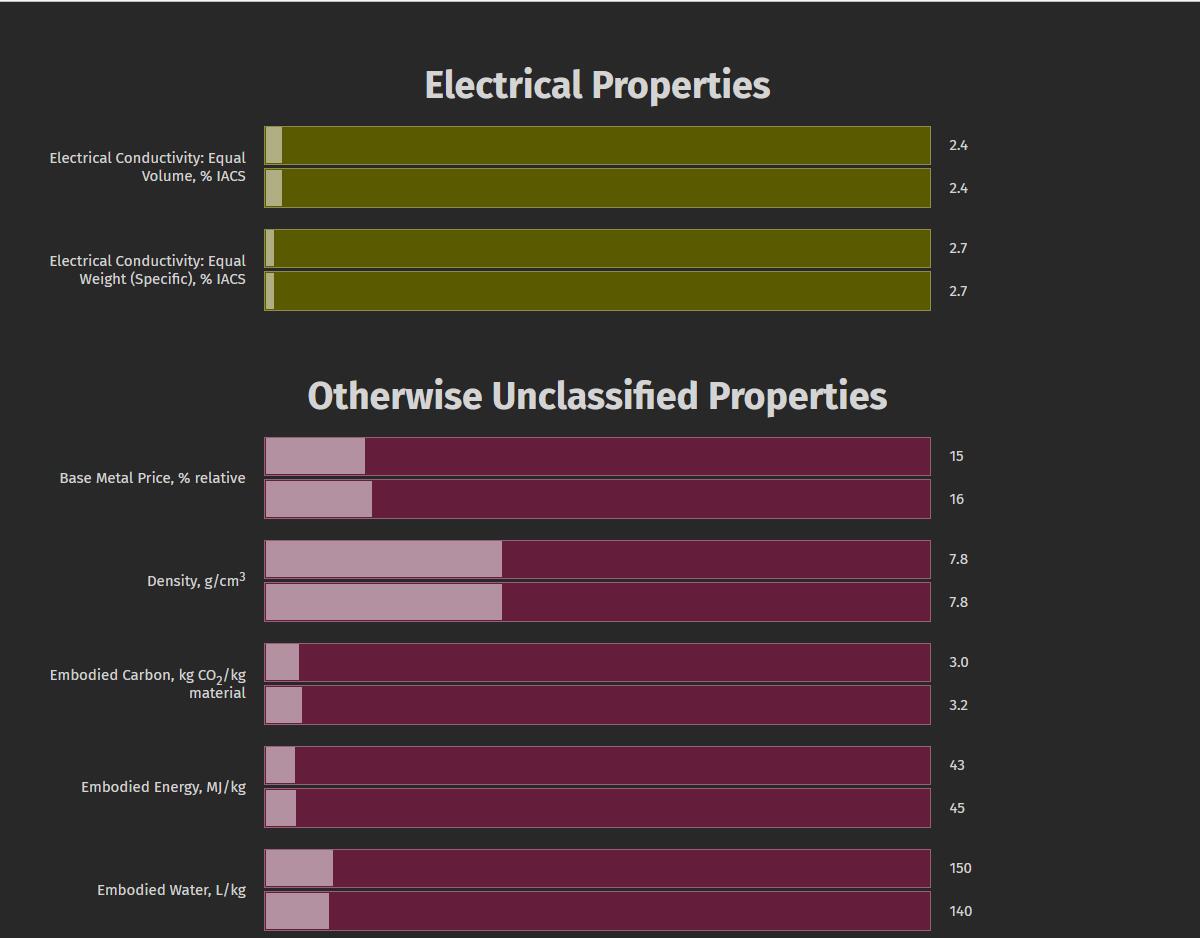

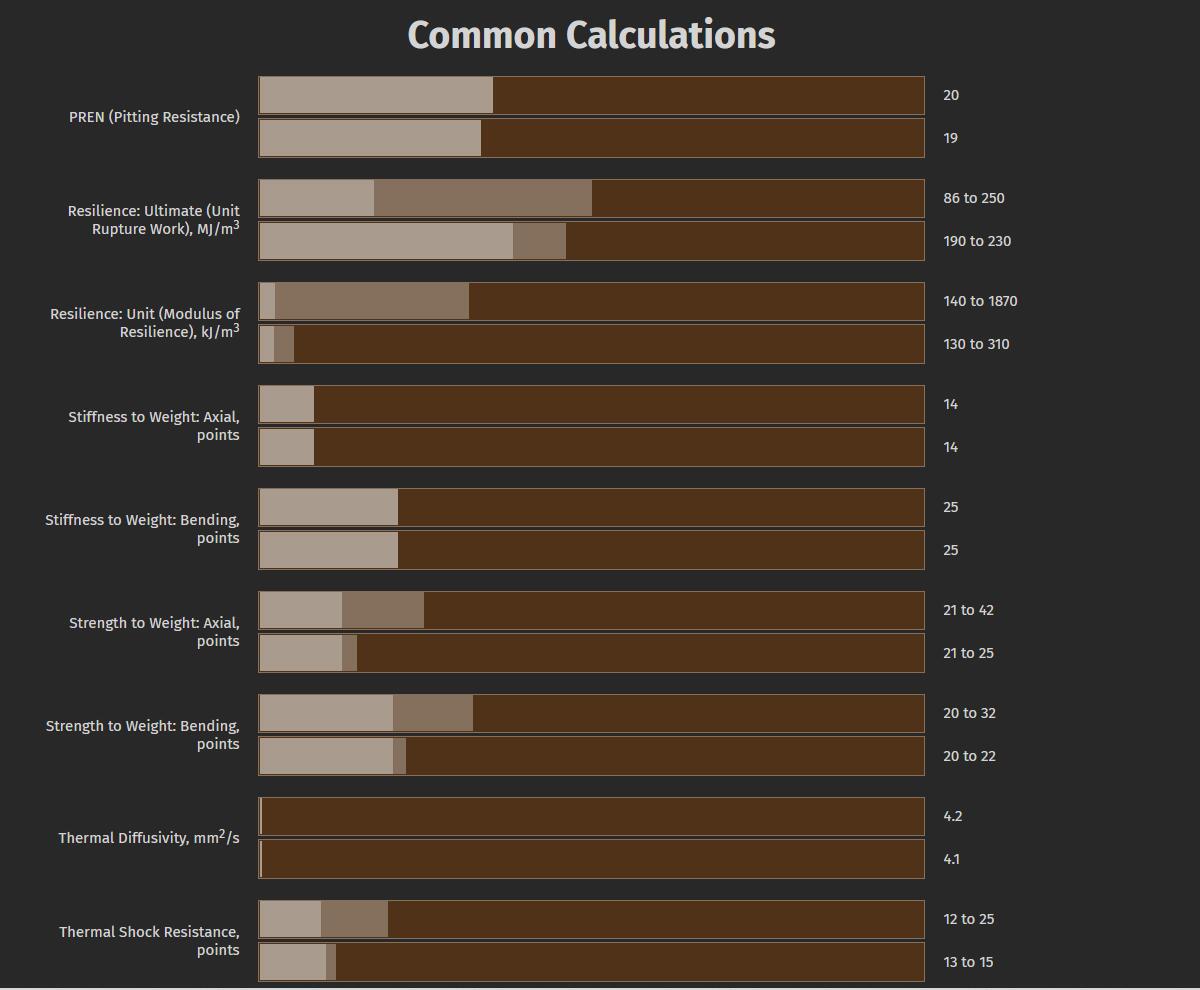

For each comparative property, the upper bar is AISI 304 stainless steel while the lower bar is AISI 321 stainless steel.

©COPYRIGHT METART BUILDING TEC CO., LTD | ALL RIGHTS RESERVED | PRIVACY POLICY